Screw Press Forging Machine For Sale in China

With the change of product structure and the continuous improvement of quality, it is also faced with the huge pressure of environmental protection and rising labor costs. In order to improve the competitiveness of enterprises, advanced equipment and technology must be used. This provides a new opportunity for the development of Electric Screw Forging Presses. Electric Screw Forging press will be developed in a heavy and intelligent direction.

With the economic development of the high-speed railways, ships, electric power, construction machinery, and other industries and the needs of national defense and security, especially the development of aerospace products and other major technical equipment, the demand for large-scale die forging equipment is more urgent.

Forgings are widely used in the aviation industry and are mainly used to manufacture key and important parts of aircraft and engines that are subjected to alternating loads and concentrated loads. Such as frames, beams, blades, rings, etc. in the engine, landing gear, joints in the aircraft body, discs, and shafts, the metal materials used are mainly aluminum alloys, titanium alloys, and high-temperature alloys, ultra-high-strength alloy structural steel, stainless steel Wait. For the development and production of large, integral, high-quality, and precise aviation die forgings, the market demand for 10,000-ton screw presses is optimistic.

The continuous increase in the installed capacity of nuclear power and wind power generation, and the demand for forgings such as large blades also provide space for the development of heavy-duty screw presses.

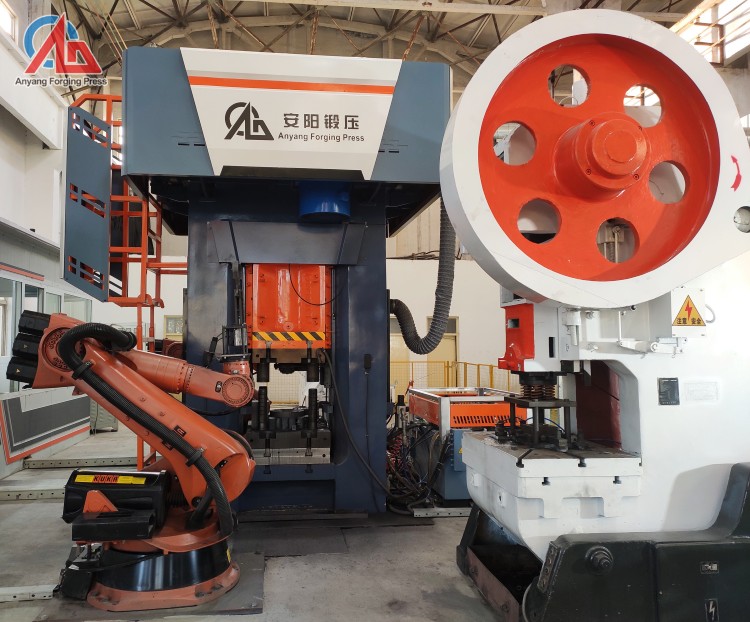

The Electric Screw Press Forging Machine adopts computer control and integrates energy control, striking force display, lubrication device, ejector device, control of loading and unloading mechanism, and fault alarm. It is necessary to further develop the intelligent control system, so that the equipment has functions such as automatic monitoring of operating status, automatic fault judgment, automatic adjustment of process parameters, and real-time forging measurement, so as to reduce the failure rate and the difficulty of failure analysis. This is of great practical significance for improving the quality of forgings, reducing the scrap rate, reducing labor costs, and reducing labor intensity.

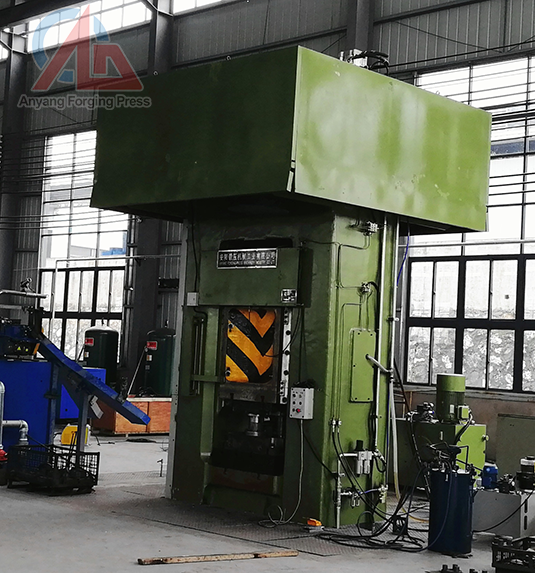

Although the Electric Screw Press Forging Machine is larger than the one-time equipment investment of the friction press, considering factors such as labor cost, energy consumption, maintenance, and product quality, from the perspective of long-term development and development trends, in order to improve the competitiveness of enterprises, It is an inevitable trend for Electric Screw Press Forging Machine to replace friction presses.

****************************************************************************************************************************************************************

If you are interested in it, pls contact me.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870