Home » Closed Die Forging Machine » Electric Screw Press (J58K) » Comparison of Electric Screw Forging Press and Friction Forging Press

Comparison of Electric Screw Forging Press and Friction Forging Press

The Electric Screw Forging Press is a kind of forging equipment with strong technological applicability, which takes into account the dual properties of forging hammer and press and has the characteristics of simple structure, small volume, and short transmission chain.

A friction Forging Press is a kind of screw press with a friction drive, also known as a double disc friction press.

Contact US

Get Price

Share:

Content

Friction Forging Press

- Due to the Friction Forging Press‘s versatility in use, the advantages of simple structure, installation, manipulation, and auxiliary equipment, and its low price, it is widely used in stamping workshops, forging workshops, and other industries in machinery manufacturing, automobiles, tractors, and aviation industries. Die forging workshops are widely used, and can also be punched. The Friction Forging Press is also a building material machine, which is widely used in the dry pressing and forming of ceramic tile, terracotta, and refractory products.

- However, the transmission efficiency of the friction press is low, about 0.65 when the slider goes down, and about 0.35 when the slider returns. The friction belt is a wearable part and needs to be replaced frequently. The striking energy of the friction press is not easy to precisely control. Moreover, due to the large energy loss, large vulnerable parts, low work efficiency, and high labor intensity of workers in the process of kinetic energy transmission, it is far from meeting the needs of industrial production in the new era.

Electric Screw Forging Press

- The striking energy of the Electric Screw Forging Press can be accurately set, and the striking force is displayed. The energy and striking force can be adjusted according to the molding precision, so as to reduce the mechanical stress and thermal contact time of the mold and prolong the life of the abrasive tool. Each Electric Screw Forging Press has two transmission forms: one is an Electric Screw Forging Press transmitted through a primary gear, with specifications ranging from 0.4MN to 80MN, and the other is a direct-drive Electric Screw Forging Press with specifications ranging from 0.16MN to 16MN. , The press body has good rigidity, high slider guiding accuracy, strong anti-eccentric load capacity, and can be used for multi-position die forging. It is a new type of energy-saving and environmentally friendly press.

- The Electric Screw Forging Press designed by Anyang Forging Press Company Production adopts gear transmission mode and special motor, with high speed, small torque, convenient and simple maintenance, and the performance of the motor will not be affected by the wear of the screw guide sleeve.

- Electric Screw Forging Press is suitable for various processes such as precision forging, finishing, precision pressing, embossing, calibration, and leveling. The Electric Screw Forging Press can be used not only for hot forging, but also for fine forging and finishing; it is not only suitable for the pressure welding process of stainless steel double bottom pot, but also for the precision forging of titanium alloy blades and other blades.

- In terms of control, the Electric Screw Forging Press can precisely control the striking energy, no excess energy is released on the mold, and the mold life is greatly improved. According to statistics, the mold life of the friction press is generally less than 4,000 pieces, while the electric screw press mold The lifespan is generally more than 15,000 pieces, and some even exceed 50,000 pieces.

- When the slider of the Electric Screw Forging Press is stationary, the motor does not work and the power consumption is low. More than 20% power saving than friction press.

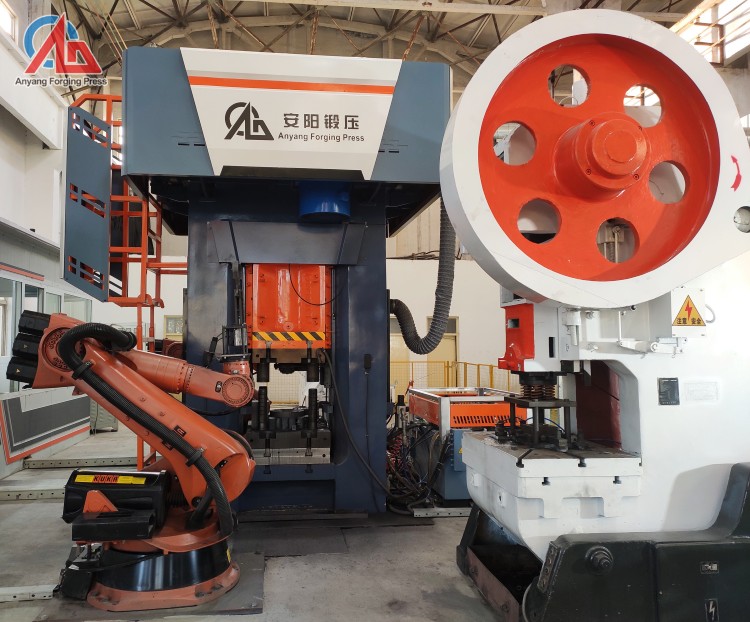

- With an Electric Screw Forging Press as the core equipment, Anyang Forging Press Company can provide forging users with one-stop forging production line solutions, including blanking equipment, heating equipment, pre-forging equipment, forging robots, forging equipment, trimming equipment and integrated systems, etc.

****************************************************************************************************************************************************************

If you are interested in it, pls contact me.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

Inquiry

More Electric Screw Press (J58K)