Electric Screw Press Hot Forging Production Line Features and Applications

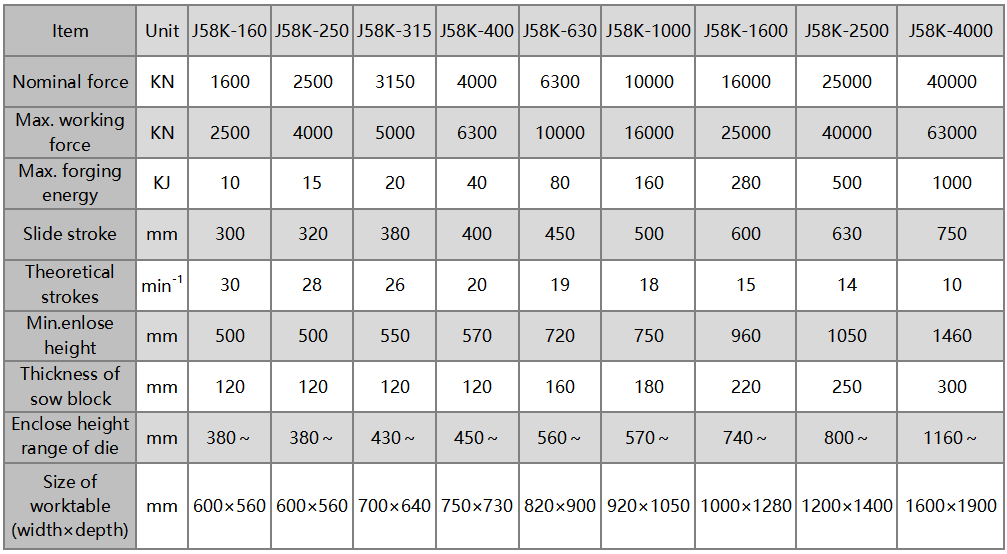

During the operation of a hot die forging press, factors such as excessively low blank heating temperature, cooling of the heated blank during forging transfer, volumetric tolerances, and incorrect adjustment of the press’s closing height can all lead to a sharp increase in die forging force, resulting in press overload or stalling. Therefore, correctly selecting the nominal force of a hot die forging press remains crucial for ensuring proper and reliable operation.

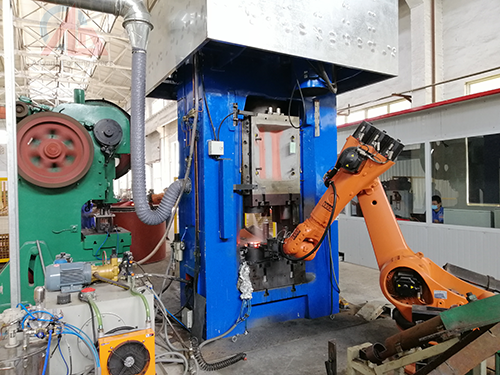

Electric screw presses offer steady energy release, minimal overall vibration, and minimal die runout during forging. Combined with forging robots, they can be smoothly integrated into various automated forging production lines, adapting to the demands of modern intelligent factories. The versatile, intelligent electric screw press is poised to become a rising star in the forging industry.

Electric Screw Press Hot Forging Production Line Features

High Efficiency and Automation

Electric screw presses are typically equipped with advanced automatic control systems that enable automated loading and unloading, pressure control, and forging parameter adjustment, significantly improving production efficiency and reducing labor costs.

Precise Pressure Control

Employing an electric servo system, they deliver highly accurate and stable pressure output, ensuring consistent dimensions and quality of forged products. Pressure can be precisely adjusted to meet diverse process requirements.

Flexibility

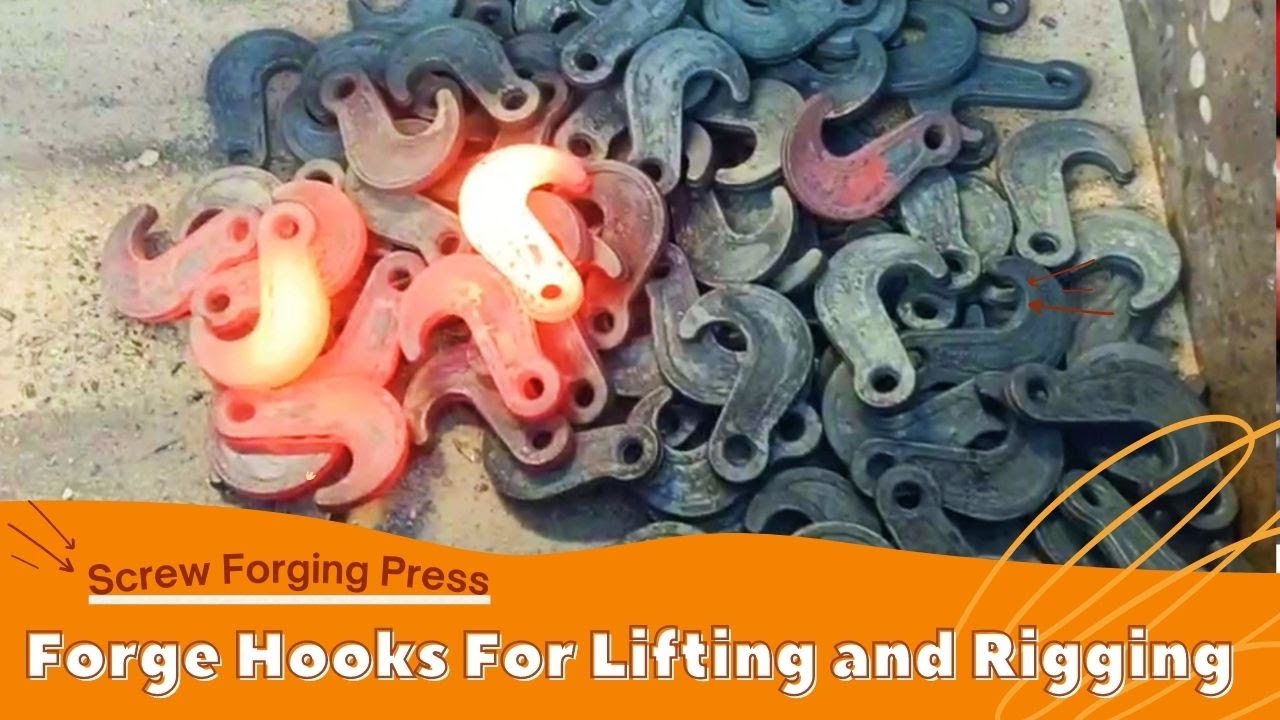

Electric screw presses are suitable for a variety of complex forging processes, processing workpieces of varying materials, shapes, and sizes, offering high process adaptability.

Efficient Energy Utilization

Electric systems offer high energy conversion efficiency, reducing energy consumption, and are environmentally friendly and energy-saving, meeting modern industrial energy conservation and emission reduction requirements.

Electric screw press hot forging production lines are widely used in various forging processes in the automotive, aviation, machinery manufacturing, hardware and other industries. They are particularly suitable for forging tasks requiring high precision and quality. This directly reflects the unique advantages and conditions of electric screw presses in the field of deep cavity forging.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.