When upgrading equipment or planning new production lines, electric screw presses should be given priority. This is especially true for businesses with high-volume production, high precision requirements, a desire to improve automation levels, and a focus on long-term overall operating costs. Electric screw presses are not only a tool for replacing old equipment, but also a strategic investment for enhancing core competitiveness and achieving transformation and upgrading.

User Background: A manufacturer of precision-forged gears for the automotive industry.

Original Equipment: Two 1,600-ton friction presses.

Pain Points:

Gear blank thickness tolerances fluctuated widely, resulting in unstable and costly subsequent finishing allowances.

Energy consumption was high, resulting in high electricity costs.

Reliance on experienced operators resulted in inconsistent product quality and a scrap rate of around 3%.

Noise levels were high, making it difficult to recruit workers.

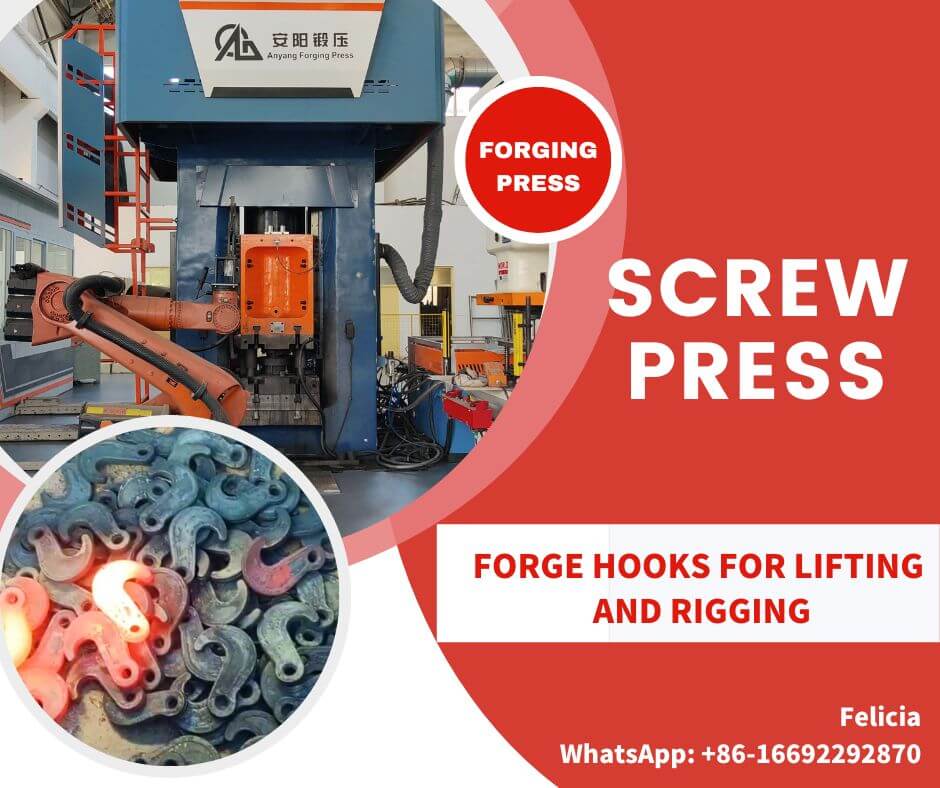

Solution: An electric screw press (with a slightly larger tonnage to achieve a wider process window) was introduced.

Results:

Quality Improvement: By precisely setting the impact energy, the thickness tolerance of the gear blanks was controlled within ±0.3mm.

Cost Reduction: Improved yield and material cost savings.

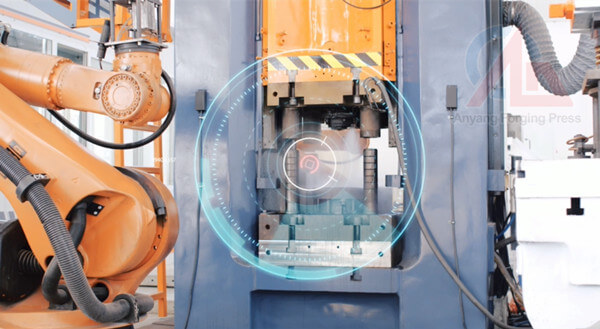

Automation Upgrade: Integration with a six-axis robot enabled fully automated production, reducing the number of workers required for three shifts from three to one (responsible only for line monitoring and spot checks).

Environmental Improvement: The workshop noise level was significantly reduced, the environment became cleaner, and the company’s image was enhanced.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.