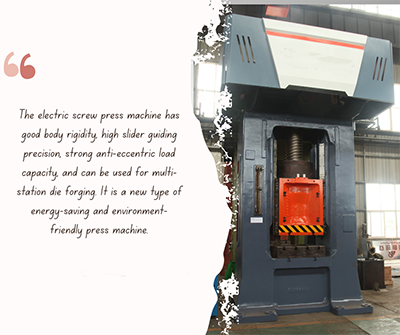

Before choosing an electric screw press for forging, you must first understand the electric screw press for forging. What is an electric screw press for forging? The electric screw press for forging is a kind of forging equipment with strong process applicability. It has the characteristics of great versatility, simple structure, easy adjustment and maintenance, no bottom dead center of the slider, easy mold design, and high precision of forgings. The electric screw press for forging is suitable for various processes such as precision forging, finishing, precision pressing, embossing, alignment, and leveling. The electric screw press for forging has the characteristics of a simple structure, small volume, short transmission chain, convenient operation, safe operation, and a small maintenance workload. force and prolong the life of the mold.

The modern forging industry has to face the huge pressure of environmental protection and rising labor costs. In order to improve the competitiveness of enterprises, advanced equipment and processes must be used. The electric screw press for forging has the following advantages when working:

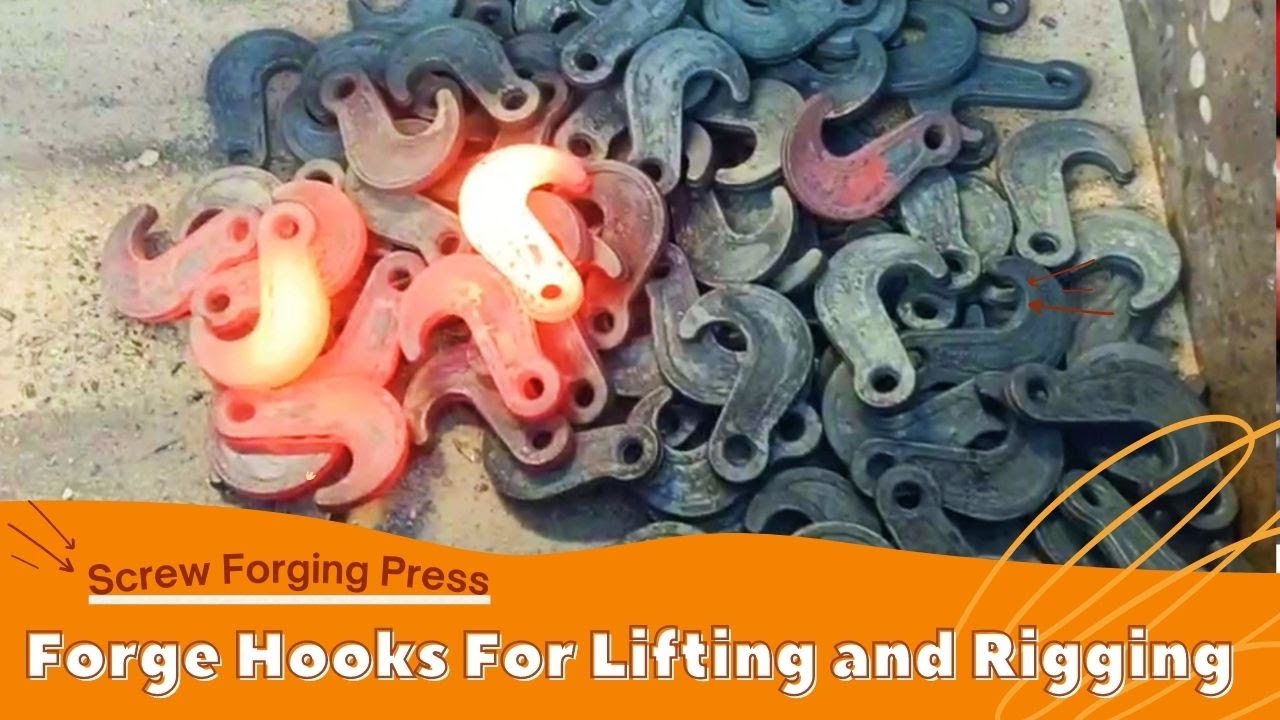

* Accurate energy control and high stroke times. The forging type is mainly used for hot die forging, and the precision pressing type is mainly used for cold forging, precision pressing, correction, bending, embossing, and other precision pressing processes of forgings such as tableware, knives, scissors, and pliers. Can be widely used in trains, automobiles, tractors, ships, aviation, hardware tools, medical equipment, tableware, and other industries;

* Simple and compact structure, short transmission chain, convenient operation and maintenance, small maintenance workload, saving labor and maintenance costs, and safe operation;

* The striking force and striking energy can be adjusted according to the forming process of the forging, the forming precision of the forging is high, the die stress is small, and the die has a long service life;

* Using advanced motor-driven electrical control technology, when the press is working, it will not impact the power grid and affect the normal operation of other equipment;

* Compared with the hydraulic screw press, there is no need for complex hydraulic drive equipment, and there is no problem of hydraulic oil leakage to pollute the environment and hydraulic failure;

* Compared with the friction screw press, there are no intermediate transmission devices such as friction discs, horizontal shafts, and friction belt wearing parts, with fewer parts, high reliability and good precision;

* There is no fixed bottom dead center, no need to adjust the height of the mold, and there will be no boring car phenomenon.

***************************************************************************************************************************************************************

If you are interested in it, pls contact me.

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870