CNC hydraulic Close Die Forging Hammer (C92K) parameters and applications

With the advancement of science and technology, the control accuracy, processing speed and automation of CNC hydraulic forging hammers are constantly improving, and intelligence and networking have become the future trend. The production needs of more high-end processing materials and complex shapes have promoted the technical update and upgrade of CNC hydraulic forging hammers.

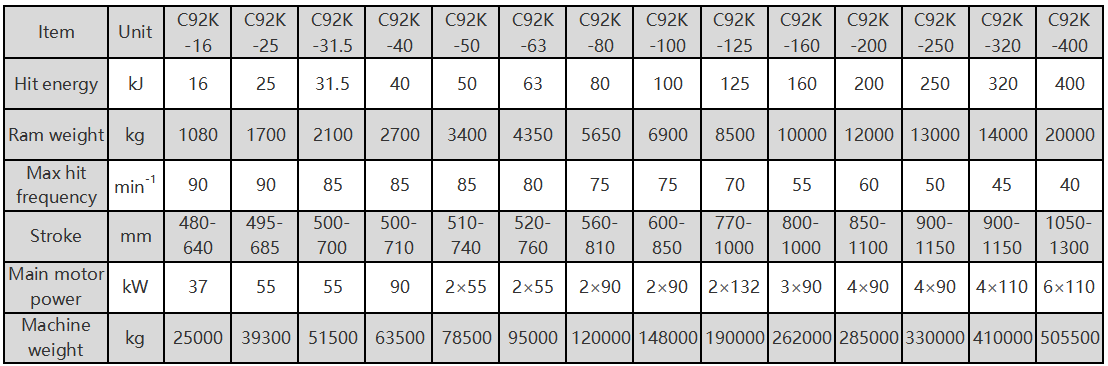

Common parameters of CNC hydraulic die forging hammer

Maximum impact force: indicates the maximum force of a single blow of the equipment, expressed in tonnage, usually ranging from a few tons to hundreds of tons.

Hammer frequency: refers to the number of hammer blows per minute, which usually affects production efficiency.

Stroke height: the distance from the highest point to the lowest point of the hammer head determines the impact depth of the hammer head.

Workbench size: the area used to place the workpiece, which affects the maximum size of the workpiece.

Motor power: the power of the drive system, which affects the generation and stability of the impact force.

Control system: the software and controller type used by the CNC hammer affect its programming flexibility and ease of operation.

Weight and size: the weight and external dimensions of the equipment itself have an impact on the load-bearing capacity and space layout of the factory.

Application fields of CNC hydraulic die forging hammer

Metal forming: used for large-scale production of metal parts, such as automobile, aerospace and machinery manufacturing industries.

Stamping: used for stamping and forming various metal materials, widely used in electrical housings, home appliance components, etc.

Mold manufacturing: In mold making, CNC hammers can be used to accurately process mold parts.

Raw material processing: processing various metal materials, such as copper, aluminum, steel, etc., to form the desired shape.

Crafts making: used to make metal crafts, especially delicate modeling processing.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.