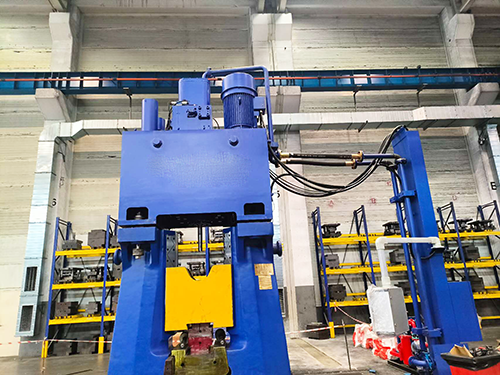

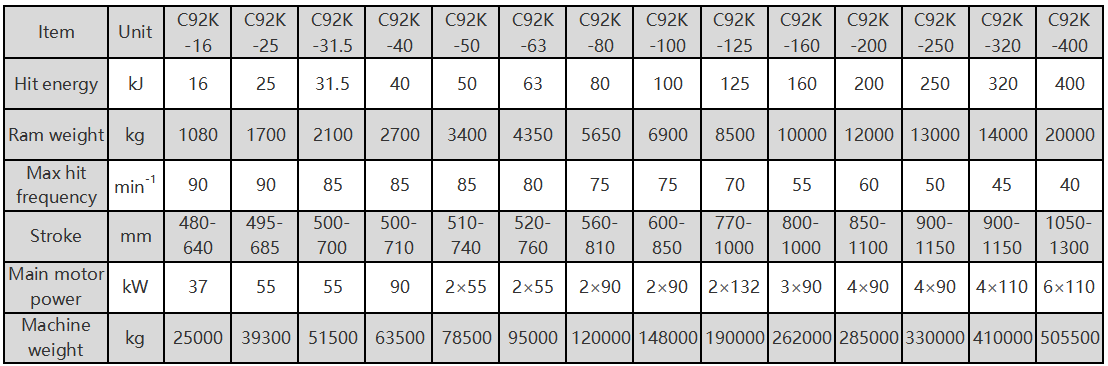

C92K Full Hydraulic Die Forging CNC Hammer Forging Automobile Connecting Rod in India

In automobile engines, connecting rods are key components that connect pistons and crankshafts, and their performance directly affects the performance and life of the engine. Therefore, the precision and quality requirements for connecting rods are very high, and CNC hammer forging technology is an ideal choice for achieving precision forging of connecting rods.

The striking energy of the CNC fully hydraulic die forging hammer is highly controllable, and the striking energy deviation can be controlled within ±3%. Compared with traditional forging, it has the advantages of higher precision, higher efficiency and more stable quality.

Main advantages of CNC hammer forged connecting rods

High precision and consistency

Using CNC forging equipment, precise die control and forging parameters are achieved to ensure that each connecting rod has consistent dimensions and meets strict industrial standards.

Excellent mechanical properties

The forging process improves the internal structure of the connecting rod, enhances its strength, toughness and fatigue resistance, and can withstand high-intensity working environments.

Realization of complex shapes

CNC forging can achieve complex geometric structures, reduce subsequent processing steps, and improve production efficiency.

Cost control

Precise process control reduces scrap rate and production costs while ensuring product quality.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.