The C92K hydraulic die forging hammer is equipped with an advanced CNC system that enables precise control of forging parameters. Multi-point sensors monitor hammer force, speed, and position in real time, ensuring that every forging meets the expected quality standards, significantly reducing defective product rates and improving production efficiency.

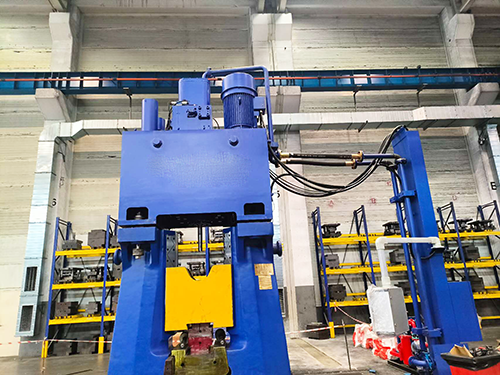

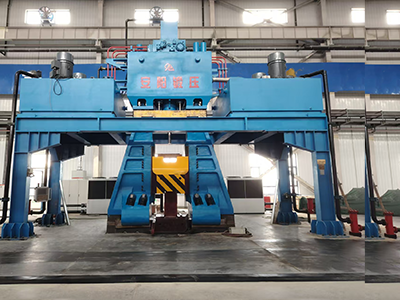

C92K Hydraulic Die Forging CNC Hammer Features

The machine body has excellent rigidity and strong resistance to off-center loads, making it suitable for multi-cavity forging.

It achieves high forging precision and a superb surface finish.

The striking energy can be superimposed, so during the forging process, one hammer cannot strike multiple blows, and a small hammer can do most of the work.

It has a wide range of applications. The CNC fully hydraulic die forging hammer can forge thin-walled forgings, special-shaped parts that are difficult to fill the die cavity, thin-ribbed forgings, and forgings with strict height tolerances.

The CNC fully hydraulic die forging hammer (programmable forging hammer) has a long die life.

The CNC fully hydraulic die forging hammer (programmable forging hammer) has a high striking frequency and high production efficiency.

Integrated with a forging robot, it can form an automated production line.

C92K Hydraulic Die Forging CNC Hammer Applications

Automotive Parts: Widely used in high-variety, high-volume production of automotive and motorcycle parts, such as automotive die forgings.

Aerospace: Suitable for precision forging of high-density, special-shaped parts in the aerospace industry.

Other Precision Die Forging Industries: Applications include construction machinery, hydraulic fittings, hardware tools, construction hardware, household hardware, medical equipment, kitchen and bathroom hardware, agricultural tools, and knives.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.