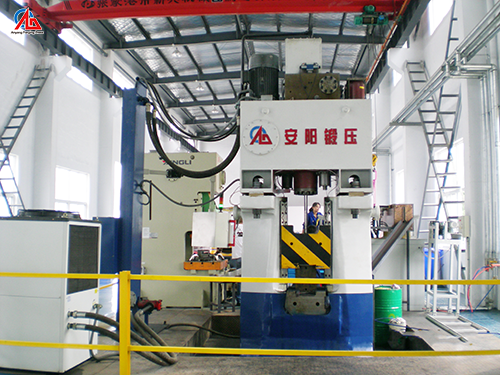

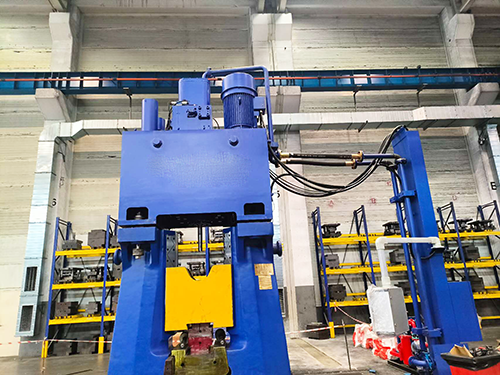

CNC hydraulic Close Die Forging Hammer forging automotive parts uses CNC technology to control the impact and movement of the forging hammer to achieve automated precision forging of key automotive parts (such as connecting rods, camshafts, etc.).

The advantages of CNC hydraulic Close Die Forging Hammer forging automotive parts include:

Efficiency improvement: quickly complete the forging process and shorten the production cycle.

High precision: ensure the consistency of the size and shape of the parts and improve product quality.

Strong flexibility: through programming adjustment, it can adapt to the production needs of different parts.

Cost reduction: in the long run, it reduces labor and scrap costs and improves economic benefits.

High degree of automation: reduce manual intervention and improve production efficiency and stability.

CNC hydraulic Close Die Forging Hammer has the advantages of high precision, strong stability and high efficiency. It can produce parts with consistent quality and precise size, improve the efficiency and product quality of automobile manufacturing, and is particularly suitable for large-scale and complex-shaped parts production.

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.