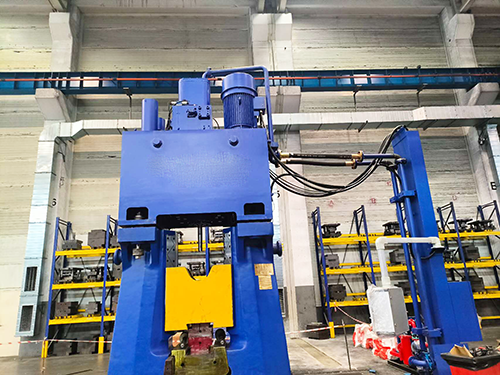

Hydraulic CNC hammer forging gear blanks is a forging process that combines hydraulic drive and CNC technology to produce high-precision, high-performance gear blanks. This process achieves efficient forging of gear blanks by precisely controlling the impact force and number of hydraulic hammers to ensure consistency in size and quality.

Advantages of hydraulic die forging CNC hammer forging gear blank:

High precision: The CNC system ensures that the parameters of each impact are consistent and the tooth shape is accurate.

High efficiency: Automatically control the forging process, significantly shortening the production cycle.

Good mechanical properties: Forging improves the density and performance of the material and reduces defects.

Adaptable to large and complex gears: Especially suitable for high-quality forging of large and heavy-loaded gears.

The application of hydraulic CNC hammers in forging gear blanks is an important technical means in modern precision forging processes. It combines the high-energy impact of hydraulic drive with CNC automation control, and can efficiently and accurately produce gear blanks that meet specifications, providing a good foundation for subsequent gear processing.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.