Fully Hydraulic CNC Die Forging Hammer Core Advantages and Development Trends

The fully hydraulic CNC die forging hammer, with its many core technological advantages, not only addresses the shortcomings of existing forging processes but also lays a solid foundation for future intelligent slag production and highly automated production. Its core advantages are primarily reflected in the following aspects:

High-precision strike control and consistency

The CNC system’s digital programming and real-time monitoring ensure that every strike adheres to strict process standards, enabling high-precision forging production. This is particularly important in high-end manufacturing sectors such as aerospace and medical devices.

Energy Optimization and Environmental Friendly

The fully hydraulic system’s efficient transmission significantly reduces power consumption and equipment vibration, enabling green and energy-saving production, in line with today’s manufacturing trend of “low carbon and environmental protection.”

Automation Integration and Digital Factory Construction

Through seamless integration with robotics and online monitoring systems, the fully hydraulic CNC die forging hammer builds an intelligent This automated production line achieves automation and intelligent control throughout the entire production process, laying the foundation for enterprises to build digital factories.

Flexible Applicability and Product Diversity

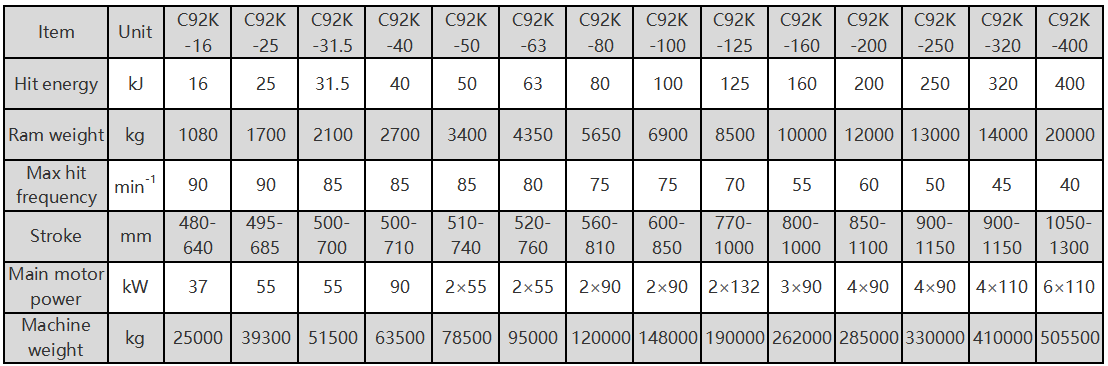

The equipment supports a variety of models and power ranges, enabling customized production of products from low to large tonnage, meeting the diverse needs of industries such as automotive, tooling, railways, and aviation. Furthermore, multi-cavity forging technology improves material utilization and economic efficiency.

Future Development Trends of Fully Hydraulic CNC Die Forging Hammers:

With the widespread adoption of Industry 4.0, more companies will transition to smart manufacturing. Fully hydraulic CNC die forging hammers will further integrate with the Internet of Things and big data technologies to achieve full-process adaptive manufacturing. Driven by the dual goals of energy conservation and environmental protection and high-efficiency production, the technical standards of this type of equipment will continue to improve, further narrowing the gap in strike energy and enhancing forging quality.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.