C92K Series Full Hydraulic Die Forging CNC Hammer Advantages of Forging Track Links

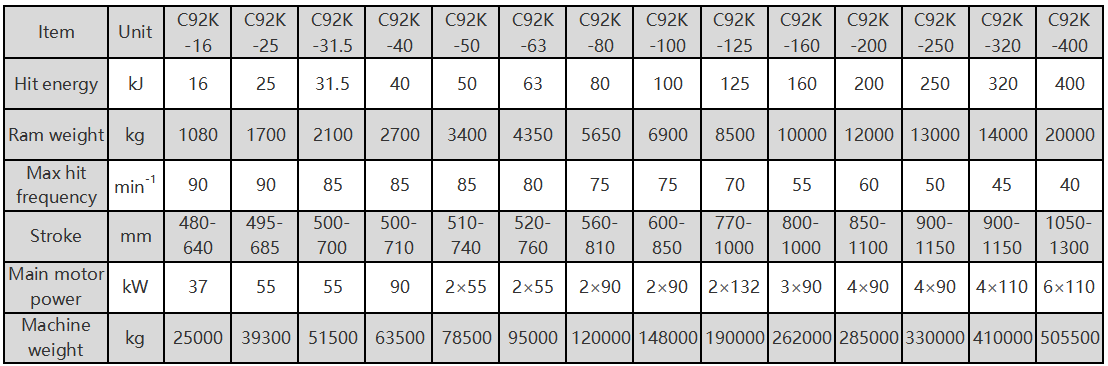

The C92K series fully hydraulic die forging CNC hammer combined with an intelligent control system enables precise forging of track links. This process ensures that each track link has excellent mechanical properties and uniform structure, improving the service life and reliability of the product.

Full Hydraulic Die Forging CNC Hammer Advantages of Forging Track Links

Efficient production, stable quality

The automated operation of CNC hammers can achieve high-speed and high-precision forging processes, greatly improve production efficiency, reduce manual errors, and ensure that each track link has consistent size and reliable quality.

Intelligent control, diverse processes

Equipped with advanced CNC systems, it supports diversified forging parameter adjustments to meet the production needs of track links of different specifications and materials. The closed-loop process achieved by CNC control ensures the stability of forging quality.

Widely used in heavy-duty equipment such as mining machinery, construction machinery, and excavators, the forged track links have excellent properties of high strength, wear resistance, and fatigue resistance, supporting long-term stable operation of the equipment.

Felicia

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.