Price of C92K series hydraulic die forging CNC hammer exported to Mexico

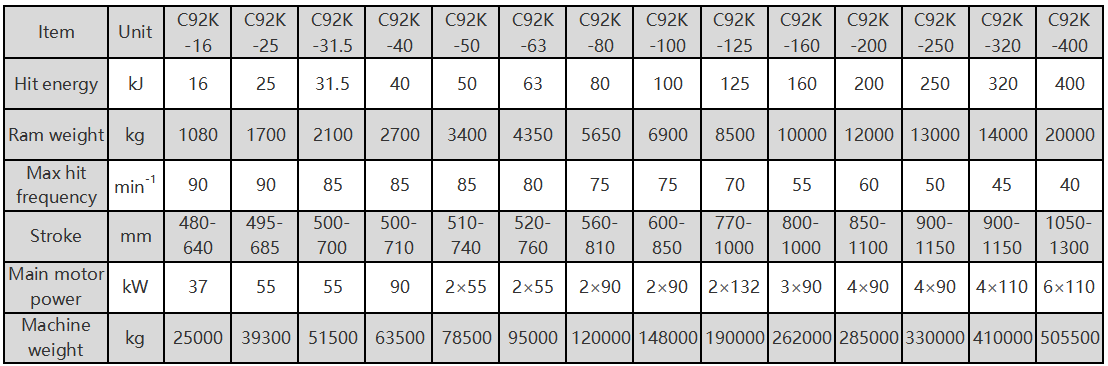

The C92K series of programmable, fully hydraulic die forging hammers utilize a one-piece U-shaped cast steel hammer body, capable of delivering striking energies ranging from 16kJ to 400kJ. This U-shaped, integral frame is now widely used and the standard. This integrally cast hammer body eliminates the need for a connection between the hammer frame and base, eliminating wear on the contact surface of the split bed and increasing the rigidity of the hammer body, significantly enhancing the hammer’s ability to withstand off-center strikes.

Owning a C92K fully hydraulic die forging hammer provides you with the following benefits:

High Rigidity and Closed-Loop Control: The fully hydraulic system provides more linear and repeatable force, displacement, and velocity control, reducing impact force fluctuations and making forging geometric tolerances easier to control.

CNC Servo System: CNC programs enable consistent, multi-step machining routes, reducing manual operation variability and improving repeatability.

Relatively Controllable Energy Consumption: Compared to mechanical or air hammers, hydraulic systems are generally more efficient in controlling cycle time and load, resulting in lower long-term operating costs.

Improved Noise and Vibration: Compared to earlier mechanical hammers, modern fully hydraulic systems achieve lower noise and vibration levels through structural design and vibration reduction measures, creating a more environmentally friendly work environment.

If you can provide specific parameters (impact force, power, number of molds, degree of automation, annual production volume, on-site power/space conditions, and budget range), I’ll prepare a technical specification sheet and quote template for comparison. I’ll help you get the latest quote. Are you ready?

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.