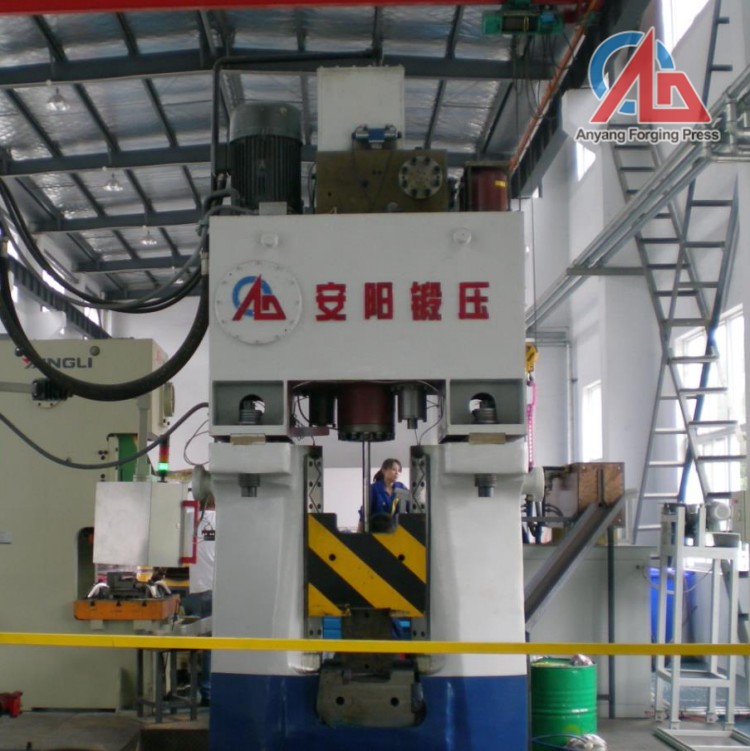

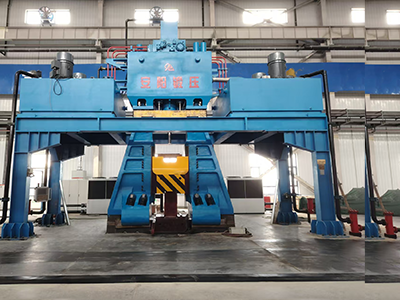

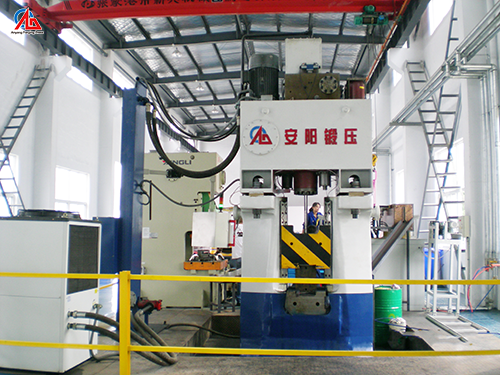

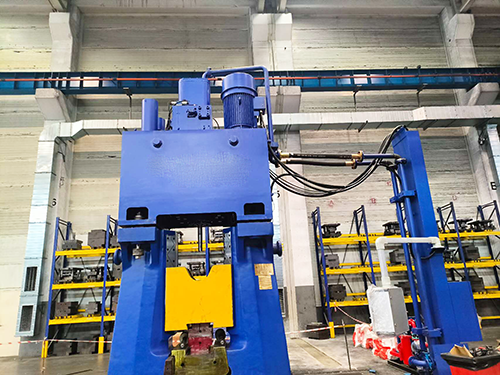

The hydraulic die forging hammer is an advanced forging machine that utilizes computer numerical control (CNC) technology. It automates the metal forging process by precisely programming the hammer’s strike energy, speed, and number of blows, replacing traditional, inefficient steam/air hammers.

Case Background: Upgrading a Wrench Forging Production Line at a Hardware Tool Company

Client Profile:

A manufacturer in East China specializes in the production of high-end hand tools (such as box wrenches and socket wrenches). Their products are primarily exported to the European and American markets, with stringent requirements for dimensional accuracy, surface quality, and mechanical properties.

Original Problems and Challenges:

Outdated Equipment: Previously, they used multiple traditional air hammers for forging, relying on the “feel” and experience of experienced craftsmen.

Unstable Quality: Product dimensions fluctuated significantly, and defects such as misalignment and underfilling were frequent, resulting in a high defect rate (approximately 5%) and frequent customer complaints.

Low Production Efficiency: Manual operation was slow and labor-intensive, leading to a labor shortage and a lack of young people.

High Costs: Low material utilization (large machining allowances), high energy consumption, and reliance on skilled labor drove up labor costs.

Harsh Environment: High noise and vibration levels, and the working environment did not meet modern enterprise standards.

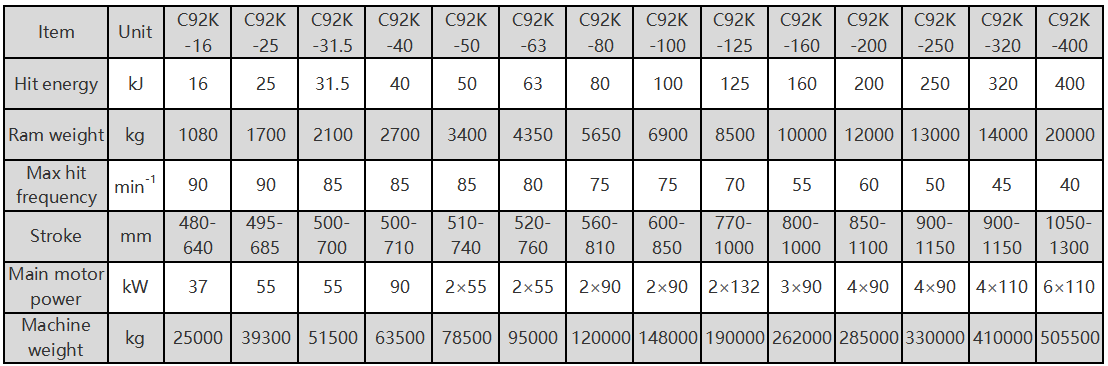

Solution: Introducing a 25kJ CNC fully hydraulic die forging hammer with an automated unit.

After extensive research, the client ultimately decided to purchase a 25kJ CNC fully hydraulic die forging hammer, along with a small automated forging unit.

Precise Positioning: The 25kJ energy is ideal for precision forging of small and medium-sized forgings weighing under a few kilograms, such as wrenches, pliers, gear blanks, valve bodies, and small and medium-sized connecting rods.

High Return on Investment: While the initial investment is higher than traditional equipment, it delivers comprehensive benefits in terms of quality, efficiency, labor, and energy consumption.

Key to Transformation and Upgrading: This involves more than simply replacing a piece of equipment; it represents an upgrade to the company’s production model, management approach, and talent structure. It is a crucial step for small and medium-sized enterprises towards efficiency and intelligence.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.