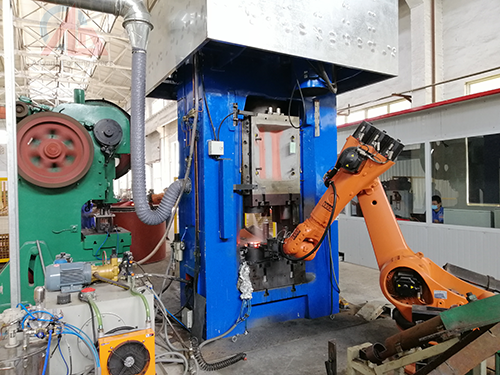

630 ton electric screw press and automated production line Features and advantages

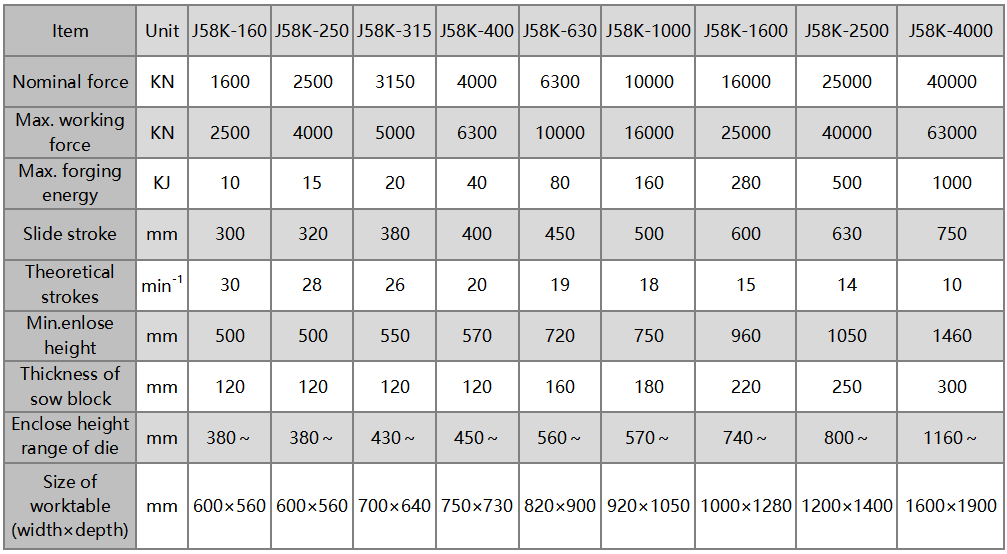

Electric screw press can be used for hot forging as well as precision forging, precision pressing, stamping, finishing and calibration. Because of its low slider speed, it has advantages in forging non-ferrous metals such as aluminum alloy and copper.

Features and advantages of Electric screw press

1. X-type guide rail and long slider structure:

The lateral and overall rigidity of the fuselage is large, the slider guide precision is high, the anti-eccentric load capacity is strong, and multi-cavity forging can be realized; the precision CNC equipment processes the lead screw and nut, the matching coupling is good, and the stability of energy output is guaranteed from both control and transmission aspects;

2. Excellent equipment safety performance:

Flywheel mechanical overload protection, overload friction and slippage, safe and reliable;

3. Energy utilization rate is improved, saving more than 40%.

Including control, display, early warning, monitoring, remote, OEE data, multi-platform support and other functions, whether it is single-machine control or automation, complete set connection is easily realized.

The electric screw press is equipped with an automatic control system, which can automatically adjust the production rhythm according to the set parameters, reduce manual intervention, and ensure safe and efficient operation. It is widely used in the mass production of automotive parts, mechanical parts and ordinary metal products, with significant advantages of energy saving and high efficiency, stable quality and easy operation.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.