Hydraulic die forging CNC hammer forging Hardware rigging Core advantages

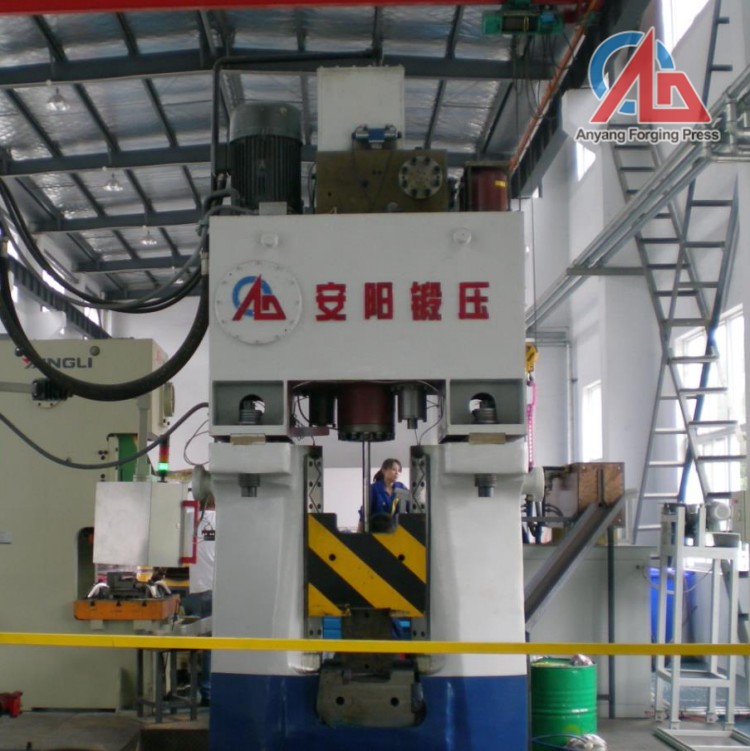

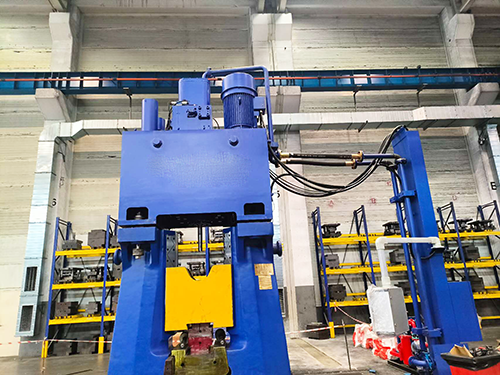

Hydraulic die forging CNC hammer forging hardware lifting rings refers to the use of CNC technology to control the hammer forging equipment to forge metal raw materials to produce high-strength and precise lifting rings. This process combines mechanical automation and forging technology to give the lifting rings better performance and consistency, and is widely used in lifting, handling and mechanical connection.

Hydraulic die forging CNC hammer forging Hardware rigging advantages:

High precision and consistency: CNC technology is used to achieve precise control of size and shape, and product quality is stable.

Strong ability to forge complex structures: It can be forged into complex ring shapes to meet the design requirements of different uses.

High degree of automation: The overall production process is automated, reducing manual operations and improving efficiency.

Excellent mechanical properties: The forging process brings high-strength, toughness, and wear-resistant rings.

Energy saving and environmental protection: Compared with traditional forging, it reduces energy consumption and waste generation, and is more environmentally friendly.

Felicia

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.