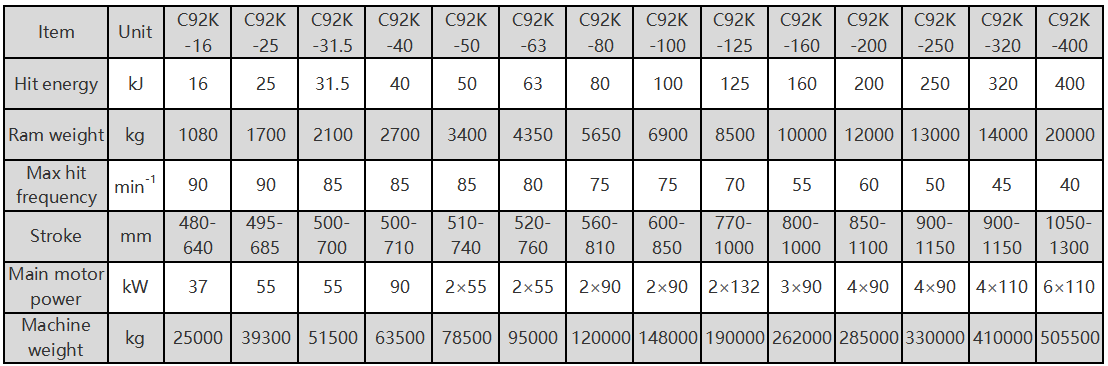

In the field of tableware manufacturing, the forging process of table knives directly affects their quality, durability and aesthetics. The traditional forging method relies on manual operation, which is inefficient and difficult to ensure precision. The emergence of hydraulic die forging CNC forging hammers has brought revolutionary improvements to table knife forging.

In the manufacture of table knives, the advantages of hydraulic die forging CNC forging hammers are particularly prominent:

Precise control: CNC forging hammers can set precise striking parameters to ensure that the forging force of each table knife is consistent, avoiding internal defects caused by uneven force in traditional manual forging.

Efficient production and reduced labor costs: Traditional forging of a table knife may require multiple heating and repeated hammering, while hydraulic die forging CNC forging hammers can be formed in one time, greatly shortening the processing time.

High material utilization rate and reduced waste: The precise striking of CNC forging hammers can reduce the forging blank surplus and reduce material loss, which is especially suitable for the forging of high-end table knife materials such as stainless steel and high carbon steel.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.