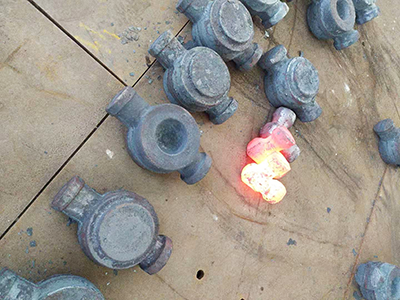

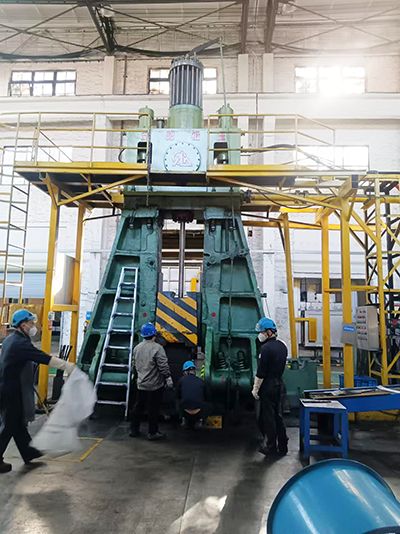

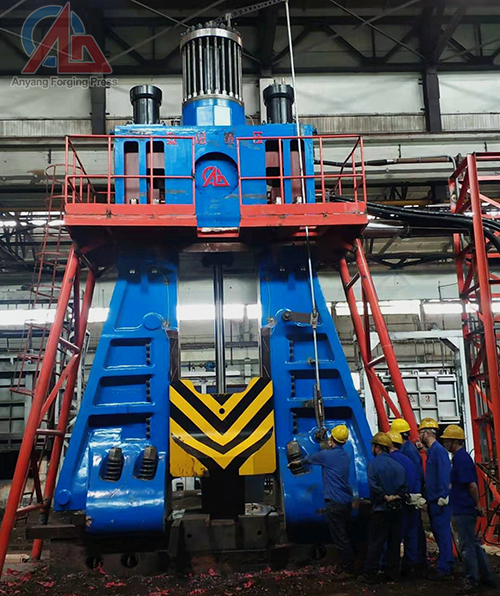

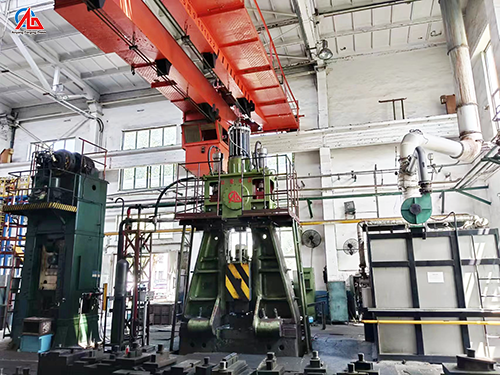

The C86Y series Hydraulic Closed Die Forging Hammer generates high pressure through the hydraulic system to push or impact the die onto the workpiece to achieve various forging operations, including stamping, hammering and plastic deformation. Hydraulic die forging hammers are widely used in the mass production of high-strength and complex structural parts in the automotive, aviation, machinery and other industries, such as shafts, gears, connectors, etc. Its advantages are high forging quality, good operating accuracy, and automation.

Hydraulic Closed Die Forging Hammer Technical characteristics

Highly integrated fully hydraulic control system, low carbon, no leakage, more reliable.

Large flow hitting valve [patent design], sensitive response, high frequency.

Built-in secondary hydraulic cushion device [patent design], realized flexible upper limit, no top hitting.

Tup returns fast, die contact time is short and will return at once, and die life is longer.

‘X’ type guide rail, can do multi-cavity forging, high forging precision, and long hammer rod life.

Automatic emergency anti hammer rod breaking cover, anti-oil leak protection, and safety.

Multilevel security protection hydraulic device, system stability, high safety.

Lead control operates the valve, reliable control, operating force is small, and low labor intensity.

Traditional hand-operated model, the original operator can operate the hammer easily.

The full hydraulic power drive system avoids the mutual exchange of oil and gas, and greatly improves the life of the hammer rod piston seal;

Unique advantage: high-cost performance, suitable for multi-variety, medium, and small-batch die forgings.

felicia@anyanghammer.com

WhatsApp: +86-13619834657

WeChat:+86 16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.