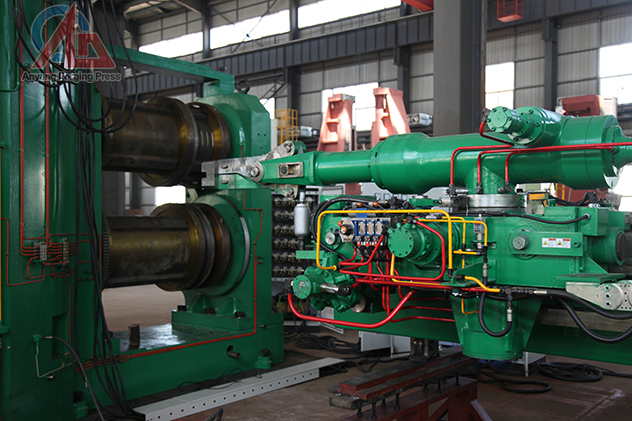

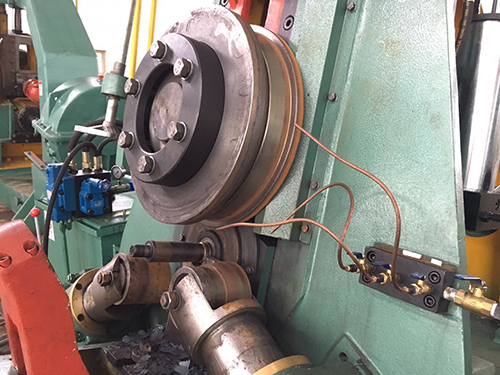

The multi-directional forging hydraulic press adopts oil-electric servo + accumulator proportional control technology, horizontal cylinder speed proportional coordinated control technology, fast flexible pressure relief technology and multi-target complete networking technology. It can realize hot fully automatic rapid multi-directional forging of metals such as carbon steel, stainless steel, copper, and aluminum alloy. It is widely used in valve body and valve cover forming and various multi-directional forging forming fields in the oil pipeline industry.

Multi-directional forging hydraulic press Features

The forgings have excellent performance and high material utilization rate;

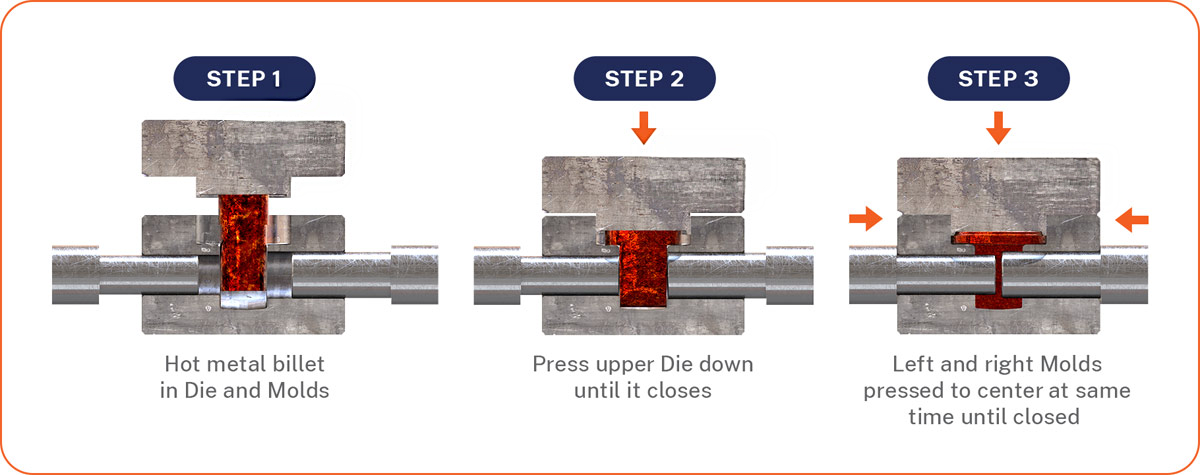

Complex die forgings with multiple inner cavities and irregular outer surface shapes are formed at one time;

The amount of subsequent machining after forging is reduced, the production cycle is short, and the production efficiency is high;

Forgings formed under high stress and large equivalent strain conditions have dense tissue;

The streamlines of the forgings are complete and evenly distributed, and the mechanical properties of the forgings are good.

The price of a multi-directional forging hydraulic press will be affected by many factors, such as the model, specification, brand, configuration, production capacity and special needs of the user. Therefore, the price range may be large.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

If you provide more detailed requirements (such as model, production requirements, etc.), you can always consult me to get the latest quotation.