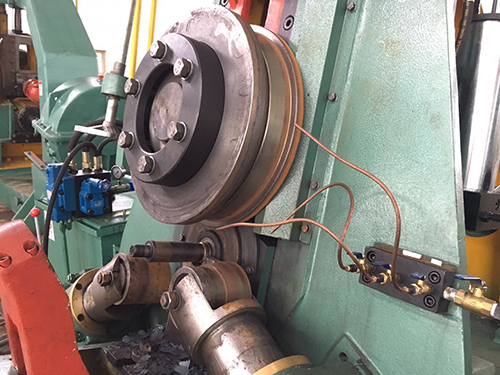

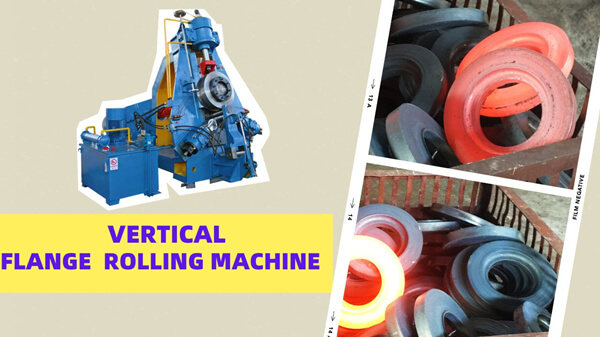

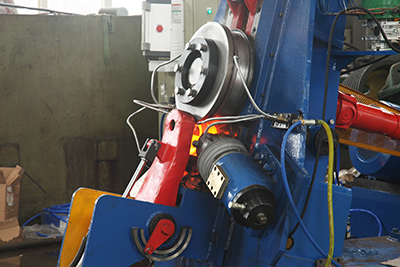

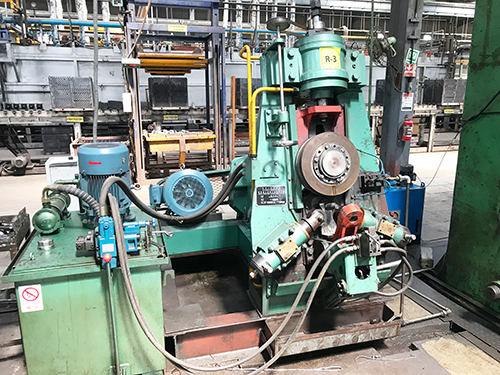

The vertical ring rolling machine deforms the ring blank by combining radial and axial rolling. Simply put, it uses rollers to apply pressure to the blank so that it continuously changes shape and size while rotating.

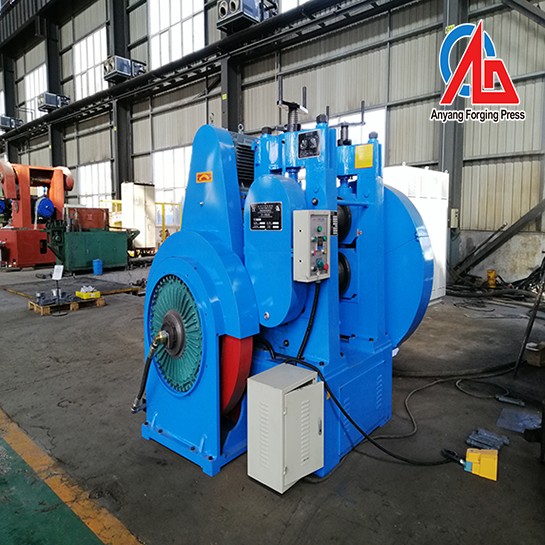

Vertical Ring Rolling Machine Core Features

The equipment boasts a small tonnage and a large processing range. The ring rolling process involves the accumulation of continuous, small deformations under localized pressure. The contact area between the workpiece and the die is small, requiring less deformation force and requiring less equipment.

Material utilization is high. The cross-sectional shape of the rolled ring is closer to the finished product, with minimal machining allowance.

Product quality is excellent. The metal fibers of the rolled ring are continuously distributed along the circumference, adapting to the forces and wear experienced during use. The rolled ring has a dense internal structure and fine grains, resulting in significantly higher overall mechanical properties than rings processed by other methods.

Working conditions are good and productivity is high. Ring rolling is similar to static pressure rolling, with virtually no impact or vibration, low noise, and easy operation. The high degree of mechanization and automation significantly reduces worker workload.

Production costs are low. Compared with open die forging, it consumes less material and energy, resulting in lower overall production costs and better economic benefits.

The price of a vertical ring rolling machine exported to India varies significantly depending on the following factors:

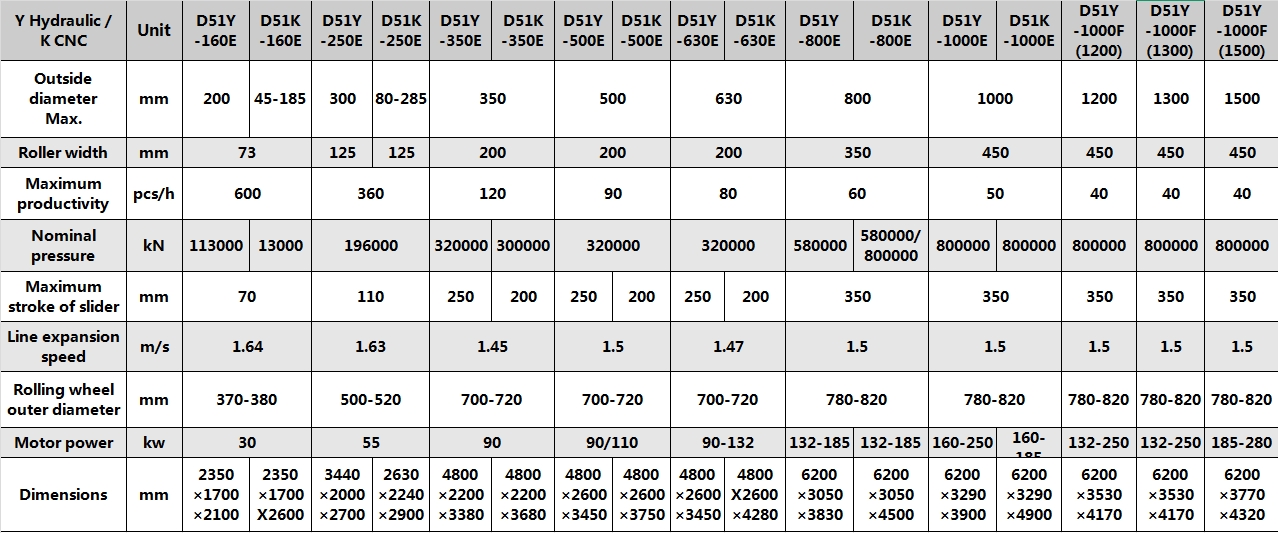

Model and Specifications: Prices vary significantly for ring rolling machines of different models, capacities, and technical parameters.

Configuration and Additional Features: Whether there are special configurations, customization requirements, or additional features will affect the price.

Quantity: The purchase quantity will affect the unit price, and bulk purchases often offer discounts.

Supplier and Brand: Pricing strategies vary between manufacturers and brands.

Transportation and Import Taxes: Shipping costs, customs duties, and import taxes to India will also affect the total cost.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.