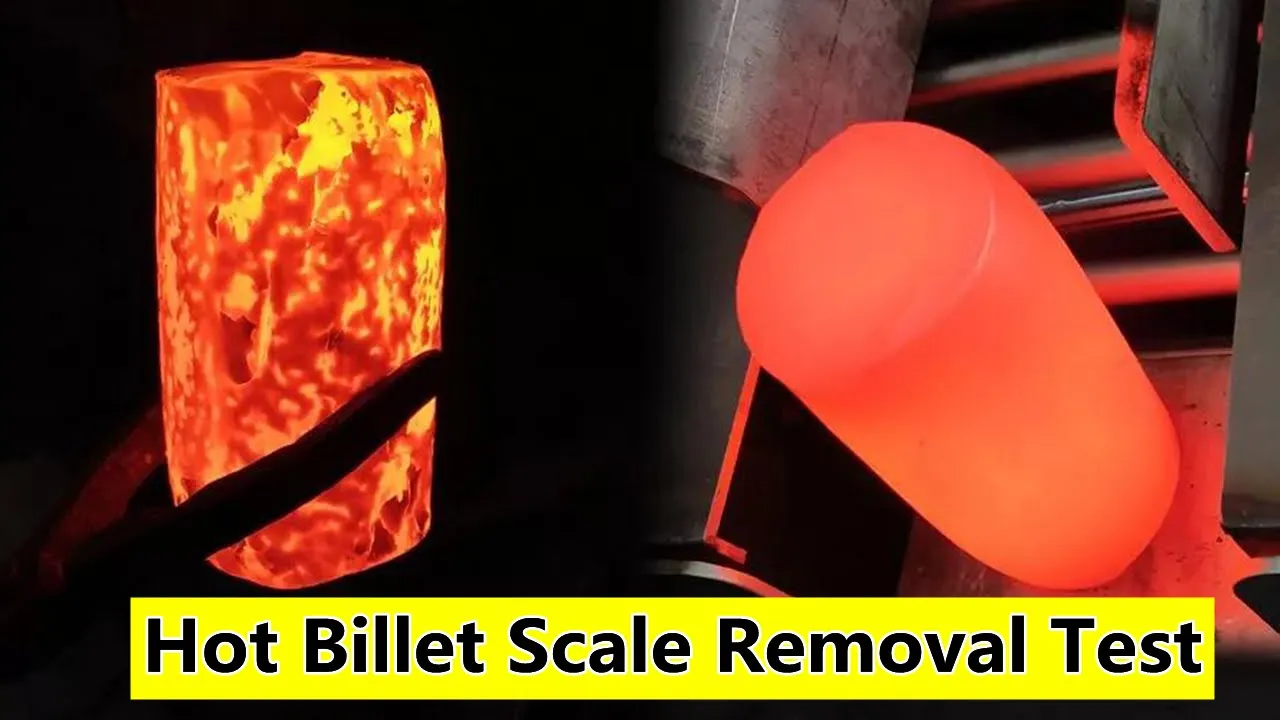

During the forging process, the forging will oxidize when heated in the heating furnace, forming a primary iron oxide scale that adheres to the surface of the forging. In addition, the forging will also undergo secondary oxidation during forging, forming a secondary oxide scale. The oxide scale on the surface of the forging will not only cause the metal to be lost due to oxidation, but also cause material shortage in the later stage of forging.

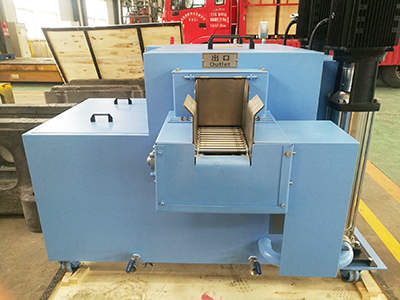

In order to effectively remove the oxide scale on the surface of forgings, the foundry has adopted many feasible dephosphorization methods in this process, which are mainly divided into manual dephosphorization, simple mechanical dephosphorization and high-pressure water dephosphorization pump.

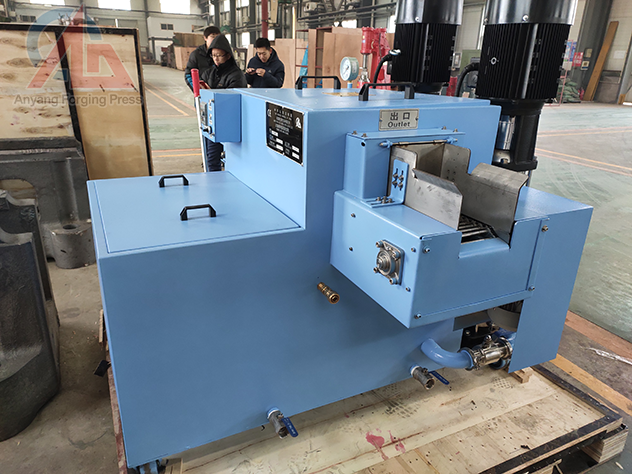

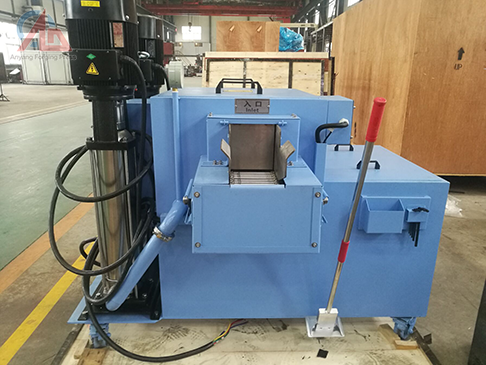

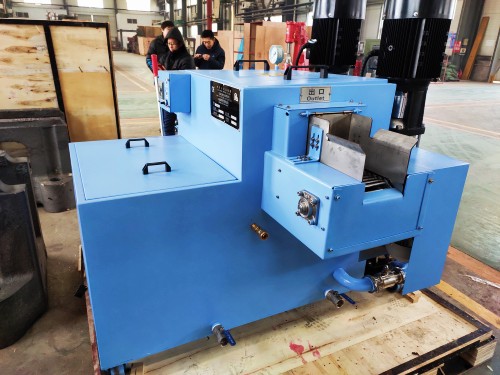

Advantages of scale removal device:

(1) Stable equipment performance;

(2) Long service life;

(3) Reduce the labor intensity of operator;

(4) Good effect of removing scale and fast speed;

(5) Automation working, and connecting with forging production line is easy.

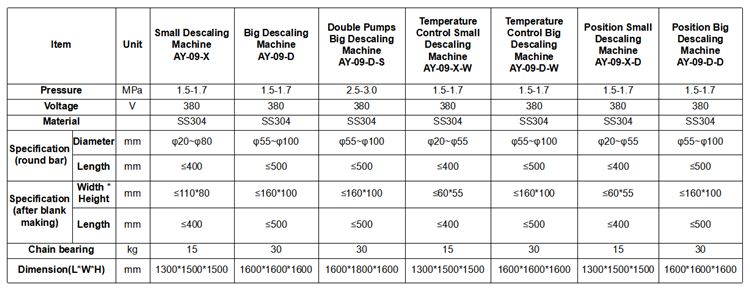

The price of Forging descaling machine varies greatly depending on factors such as equipment type, processing capacity, brand, degree of automation, etc. The following are the main factors and approximate ranges that affect the price. If a more accurate quotation is required, the specific application scenario can be further explained.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.