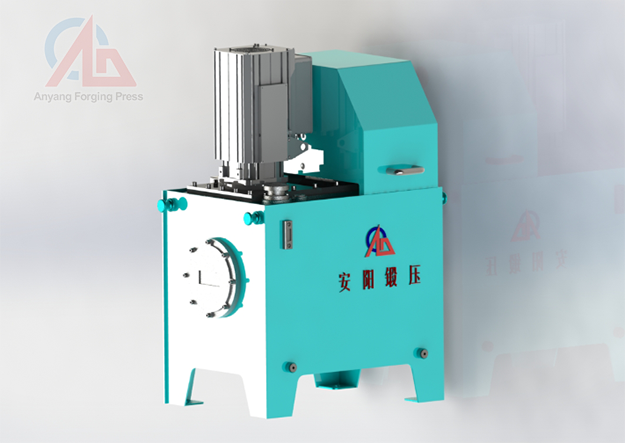

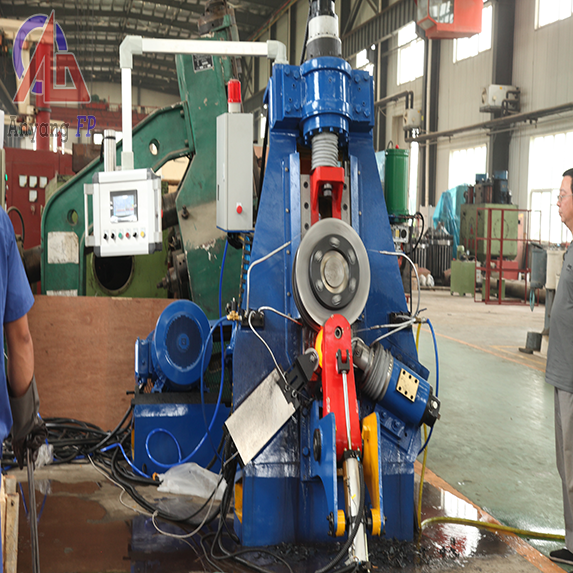

D46 series wedge rolling machine is on two axes parallel, to the same roll on the same roll, the symmetrical installation of the same rolling die.The shape of the working part of the die is shaped like a wedge.The axis of the workpiece blank is parallel to the roll and is placed between the upper, lower rolling and radial baffle plates.With the rotation of the roll, the wedge of the die is pressed into the blank and the blank is rotated to reduce the radial direction of the blank and the axial elongation.Roll rotation once a week, that is to finish rolling.When used for die forging, the material can be accurately allocated and the material utilization rate is high.The cross wedge rolling process can be one or more pieces of rolling.

Wedge rolling is an advanced forging technology. Its advantages are as follows:

- High production efficiency;

- High material utilization;

- Good working conditions, easy to mechanize and automate;

- When rolling deformation, the workpiece is only in contact with the mold, so the die life is high.

The price range of D46 series wedge rolling machine usually needs to be obtained through suppliers or manufacturers, and will vary depending on the region and market conditions. It is recommended to consult the local metal processing plant or related suppliers for specific prices.

Felicia

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.