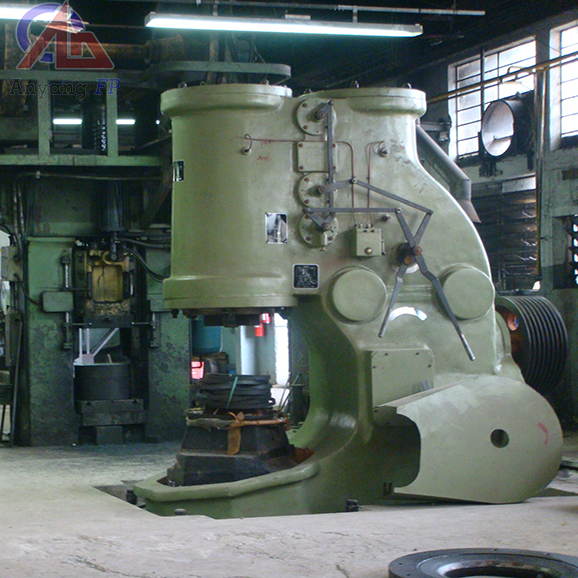

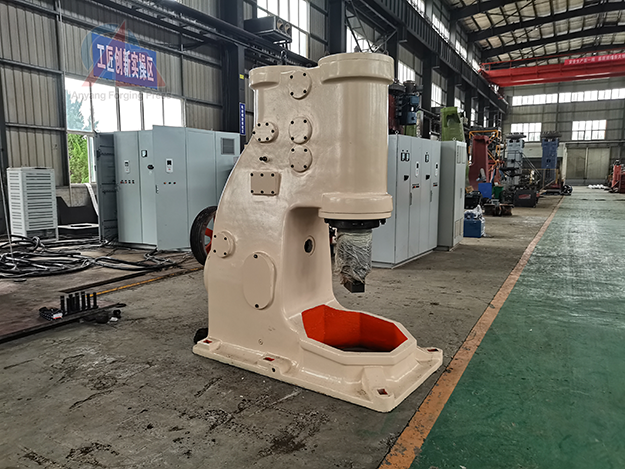

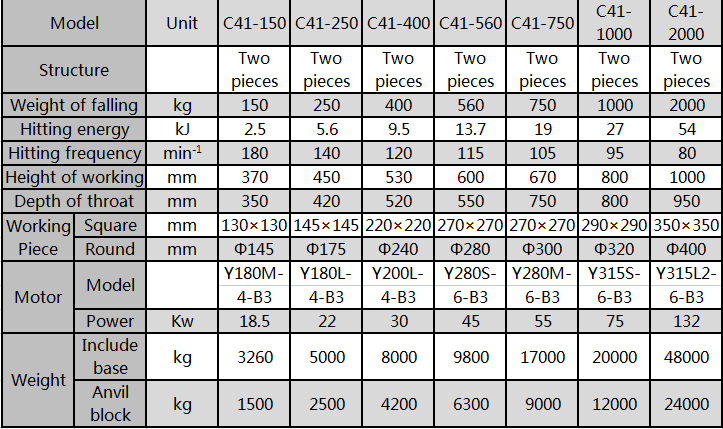

Anyang Forging is a professional air hammer manufacturer. The Anyang pneumatic forging hammers include 150KG, 250KG, 400KG, 560KG, 750KG, 1000KG, and 2000KG. They are suitable for various free forging operations such as stretching, upsetting, punching, shearing, forging welding, torsion, bending, etc. Various open die forgings can be performed using tire membranes.

Anyang Pneumatic Forging Hammer Installation Process:

Transportation and On-site Inspection

Confirm that the equipment is intact and that all packaging, bolts, and seals are complete.

Foundation and Positioning

Place the main unit in the designated location and use a spirit level to ensure the equipment is level. If foundation concrete pouring is required, it should be carried out based on the factory-provided design.

Air Supply System Connection

Install the dryer, filter, and pressure reducing valve, and connect the air pipe to the equipment interface to ensure there are no leaks.

Electrical and Control Systems

Standardize wiring routing and ensure proper fastening, shielding, and grounding. Test the emergency stop button and interlock.

Die and Punch Installation

Install the corresponding die, punch, and positioning fixture according to the processing technology, ensuring concentricity and a tight fit. Perform an initial positioning test run.

Commissioning and Performance Verification

Run the machine without load, then gradually add load. Record parameters such as impact force, frequency, noise, vibration, and temperature to ensure they are within specifications.

Anyang Pneumatic Forging Hammer Maintenance:

The air hammer has an oil pump that must be checked and refilled every three days. Additionally, two grease plugs must be lubricated every two months. Finally, check the bolts monthly for tightness.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.