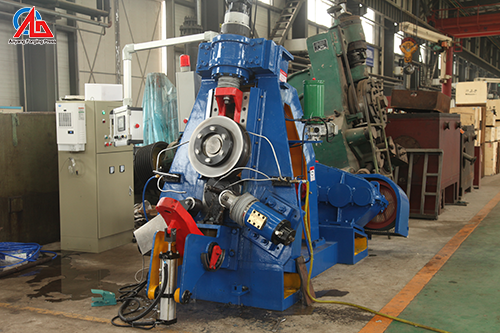

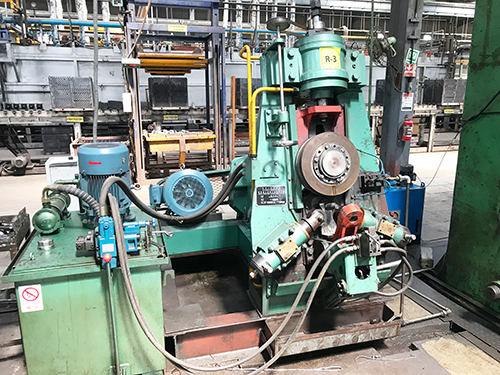

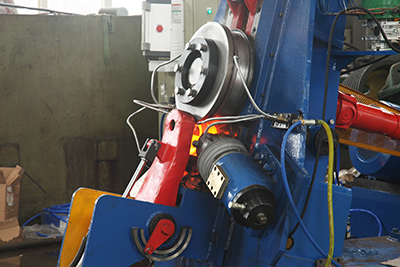

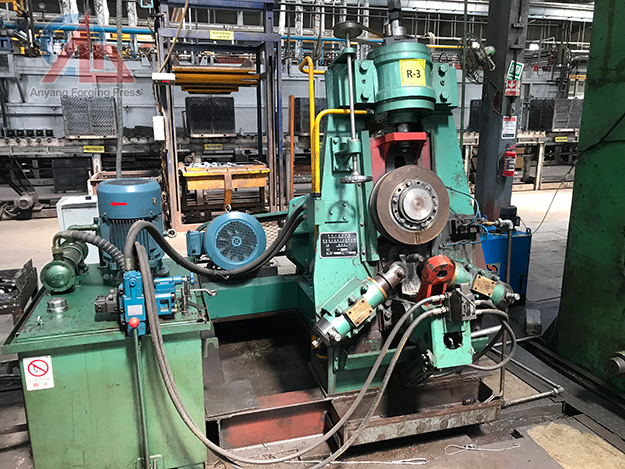

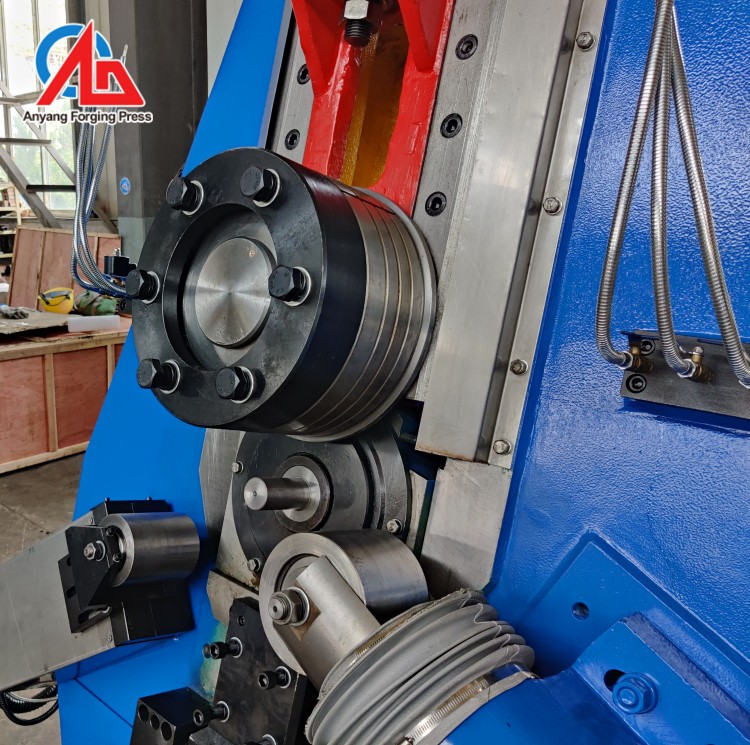

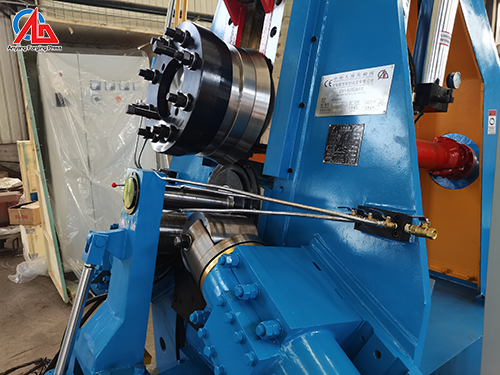

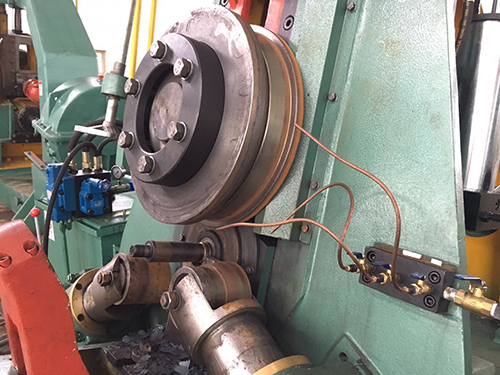

The ring rolling machine uses two or more rotating rolling wheels to press and shape the metal blank, gradually deforming it into a ring shape. The rolling wheels rotate at a certain angle and speed, applying pressure to drive the blank to continuously deform between the rolling wheels until the required ring size and shape is reached.

Ring rolling machines can be divided into the following types according to their structural form:

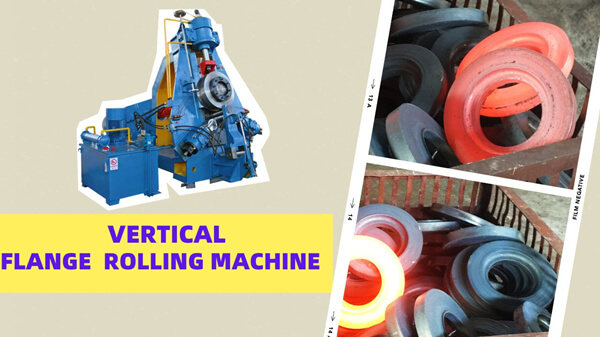

Vertical ring rolling machine: The equipment is arranged vertically, easy to maintain, and suitable for small and medium-sized rings.

Horizontal ring rolling machine: The equipment is arranged horizontally, suitable for the production of large rings.

Ring rolling machines are suitable for producing annular mechanical parts of various shapes and sizes, such as bearing rings, gear rings, flanges, hubs, thin-walled cylindrical parts, wind power flanges, high-neck flanges and other seamless annular forgings. Ring products are widely used in many industrial fields such as machinery, automobiles, trains, ships, petrochemicals, aviation, aerospace, atomic energy, wind power generation, etc.

Felicia

felicia@anyanghammer.com

WhatsApp: +86-13619834657

WeChat:+86 16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.