In the modern machinery manufacturing industry, forging technology is of great significance for improving the mechanical properties and structural strength of metal parts. Hydraulic Open Die Forging Press is widely used in high-strength forging production in the aerospace, automotive, heavy machinery and other industries due to its excellent structural design and outstanding performance.

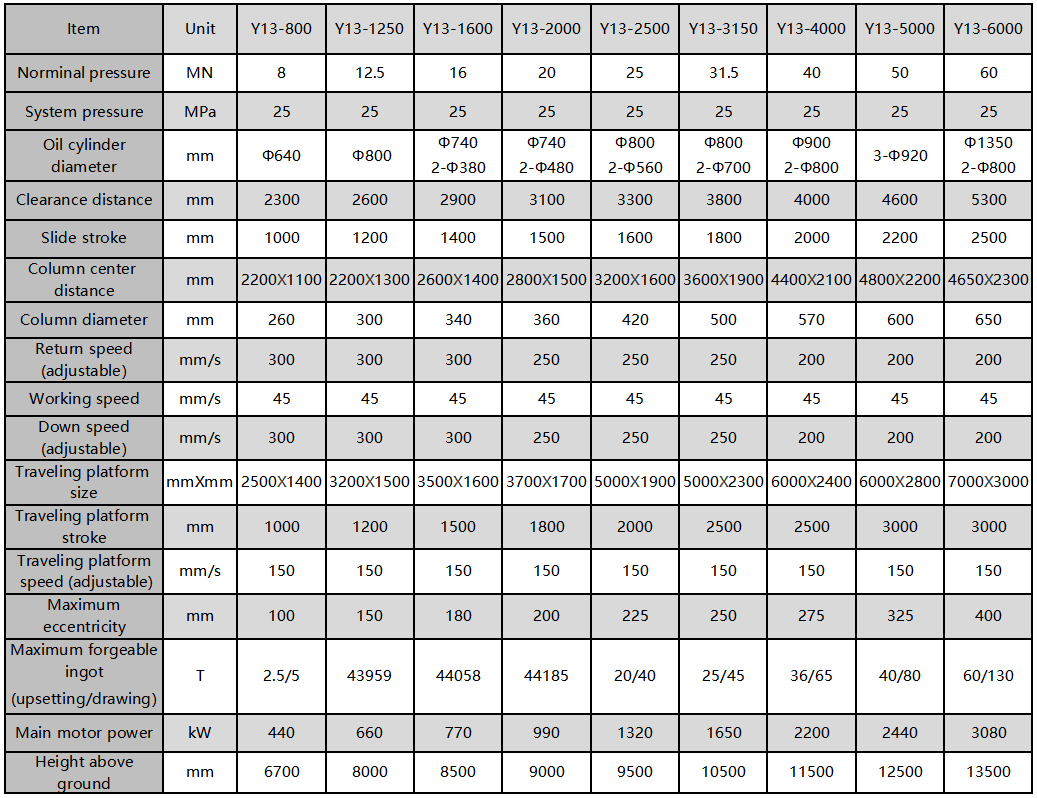

Hydraulic Open Die Forging Press Related Parameters

Maximum Pressure (Rated Pressure)

Definition: The maximum pressure that the hydraulic system can withstand, usually expressed in megapascals (MPa) or meganewtons per square meter.

Function: Determines the upper limit of the equipment’s forging capacity and affects the maximum size and weight of the parts.

Impact Capacity (Impact Force or Maximum Load)

Definition: The maximum force that the hydraulic punch can exert during the impact process, in kilonewtons (kN) or meganewtons (MN).

Function: Ensure that sufficient force is provided to deform the metal during the forging process.

Movement Stroke

Definition: The maximum moving distance of the punch or punch along the guide rail, in millimeters (mm).

Function: Related to the maximum size and forging depth of the workpiece.

Workbench Size

Definition: The work platform area or workspace size where the workpiece is placed.

Function: Affects the maximum size of forged parts.

Control system

Type: PLC control, CNC system (CNC), manual control, etc.

Function: Realize parameter adjustment, automatic operation and precise control.

The price of Hydraulic Open Die Forging Press depends on the tonnage, configuration and brand of the equipment. If you need a specific model, parameter table or quotation plan, you can tell me your specific needs (such as maximum pressure, forging size, budget range, etc.), I can help you organize more accurate information!

Felicia

felicia@anyanghammer.com

WhatsApp/WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.