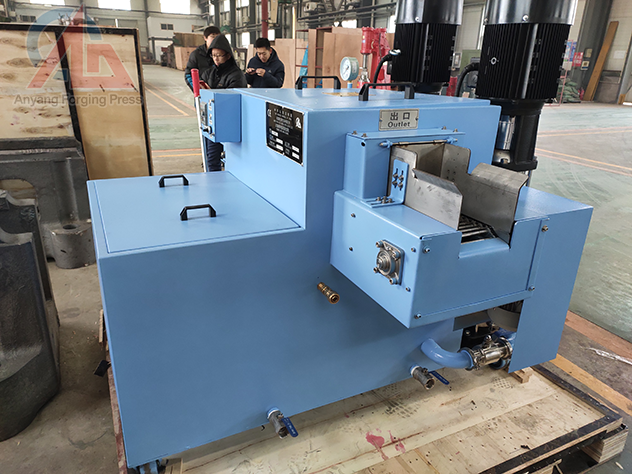

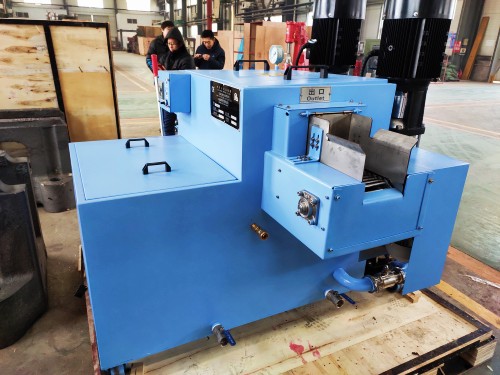

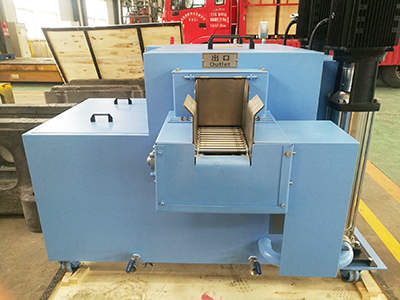

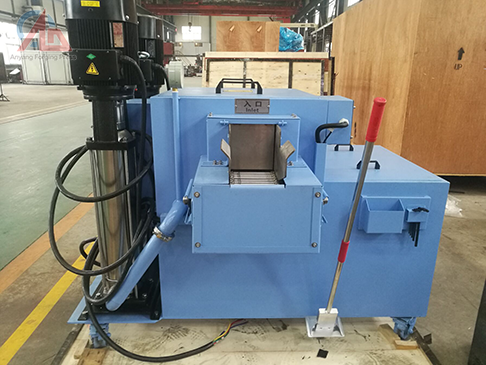

Anyang forging equipment descaling machine

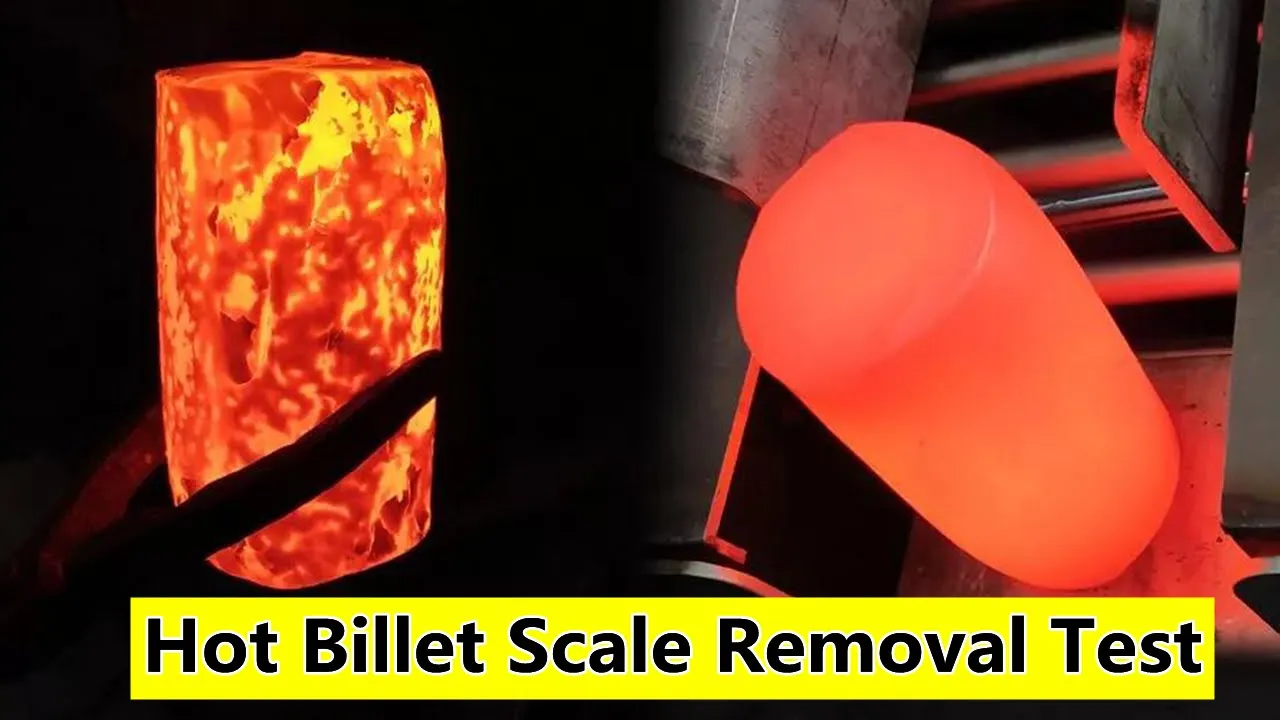

In the forging production process, the metal blank needs to be heated to a high temperature, steel reacts with oxygen on the billet surface, which will generate a layer of scale. If it can’t be removed before forging production, some pits may occur on the surface, which not only affects the appearance quality, but also reduces local strength, if these pits appear on machined parts of forging, will also reduce machining allowances, and have the risk of processing scrap.

Contact US

Get Price

Share:

Content

High-pressure water descaling. In the world of forging, high-pressure water descaling (removal of oxide scale) is already an important process in forging manufacturing (especially hot die forging). It improves the quality of forgings and reduces the prefabricated dimensions of blanks and reduces die wear. It greatly reduces the difficulty of subsequent processing and the amount of machining, which directly or indirectly reduces a lot of production costs for enterprises.

Advantages of scale removal device:

- Stable equipment performance;

- Long service life;

- Reduce the labor intensity of operator;

- Good effect of removing scale and fast speed;

- Automation working, and connecting with forging production line is easy.

- If you are interested in it, please contact me.

- Luca

- Luca@anyanghammer.com

- WhatsApp/WeChat: +86-16692292860

Inquiry

More Scale Removal Device