The Metal Bar Billet Cutting Machine is a critical pre-processing device in modern forging, hardware manufacturing, and standard parts production. Its primary function is to quickly and accurately cut metal bars (such as round steel, square steel, flat steel, and pipes) into billets of predetermined lengths, providing qualified blanks for subsequent forging, stamping, and machining processes. Its high efficiency, precision, and automation have gradually replaced traditional sawing machines, making it an ideal choice for modern mass production lines.

A metal bar billet cutting machine primarily uses tremendous shearing force to cause plastic deformation of the bar stock until it breaks. A motor drives a hydraulic pump, generating high-pressure oil. This oil cylinder pushes the piston rod and slide, exerting constant, intense static pressure to achieve shearing.

The price range of a metal bar billet cutting machine depends primarily on the following factors:

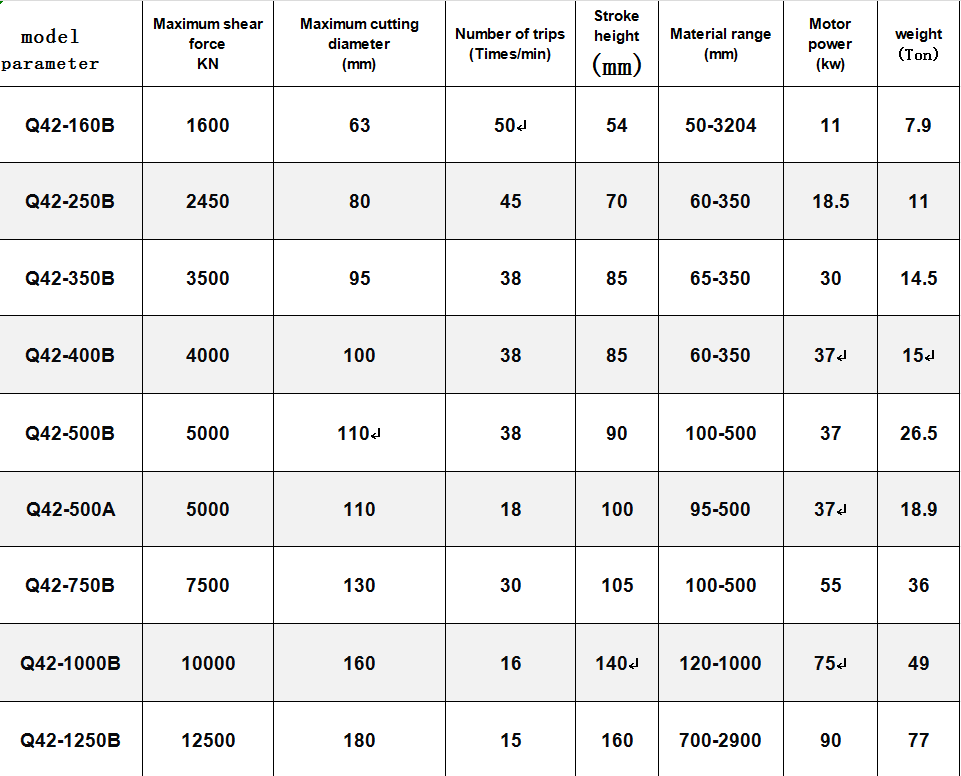

Type and tonnage: These are the most important factors. The larger the tonnage, the higher the price. Hydraulic models are generally slightly more expensive than mechanical models of the same tonnage.

Level of Automation: Manual/Semi-automatic: This machine consists solely of the main unit, requiring manual feeding and operation. These machines are the cheapest.

Fully Automatic: This machine includes an automatic feeder, a material stop, a discharge conveyor, an automatic counting and stacking system, and is centrally controlled by a PLC. This increases the price significantly.

Cutting Specifications: The maximum bar diameter and material strength that can be cut directly determine the machine’s tonnage and price.

Brand and Origin: Imported brands are significantly more expensive than domestically produced equipment.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.