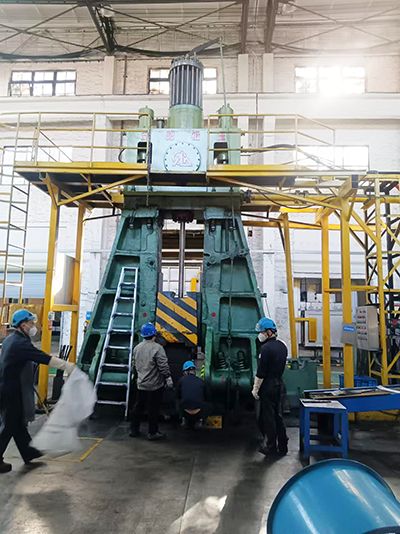

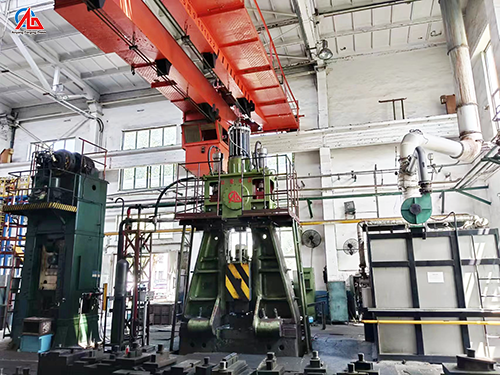

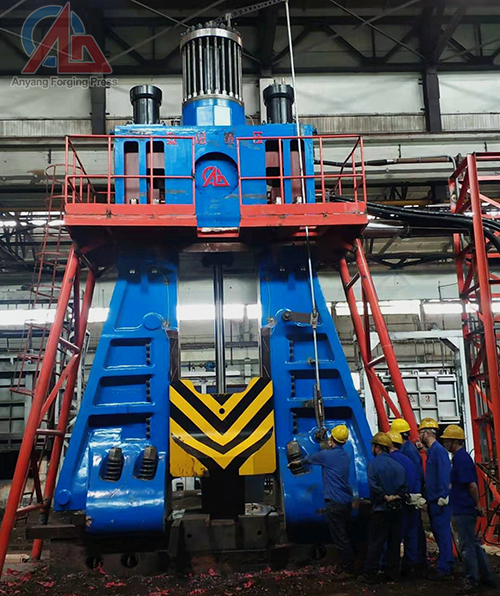

Hydraulic die forging hammer is a representative of high-end forging equipment, mainly used to produce die forgings with high precision requirements and complex shapes, such as automotive connecting rods, gears, aerospace components, etc.

The hydraulic die forging hammer’s features revolve around four core elements: precision, economy, stability, and intelligence:

Forging Precision and Consistency: The hydraulic die forging hammer utilizes full hydraulic servo control, enabling precise digital control of the hammer’s striking energy, striking speed, and stopping accuracy.

Energy Saving and Environmental Protection: The hydraulic die forging hammer consumes electrical energy during the strike, with an accumulator recovering some of that energy during the return stroke to prepare for the next strike. With no boiler, coal burning, or steam pollution, the operating environment exhibits significantly lower noise and vibration than traditional forging hammers.

Process Adaptability and Flexibility: The hydraulic die forging hammer features multiple functions, including light strike, heavy strike, suspended hammer, and emergency stop. By simply changing the die, a variety of products can be produced, making it ideal for high-variety, small- to medium-volume production.

Automation and Intelligence: The hydraulic die forging hammer can be equipped with robotic loading and unloading, die temperature control systems, and online dimensional inspection, making it easy to integrate into automated production lines.

Factors affecting the export price of a Hydraulic Closed Die Forging Hammer include:

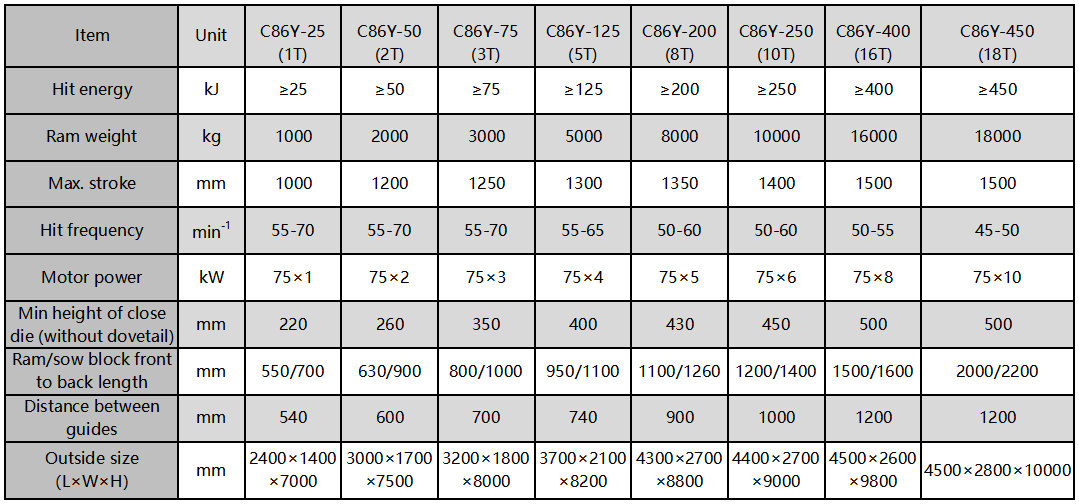

Core equipment specifications (tonnage);

Configuration and brand;

Degree of automation;

Export-related costs;

FOB (free on board) and CIF (cost, insurance, and freight) prices differ; CIF prices include shipping costs and insurance.

Installation and commissioning:

Whether the cost of sending engineers abroad for installation, commissioning, and training is included (this is usually charged separately).

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.