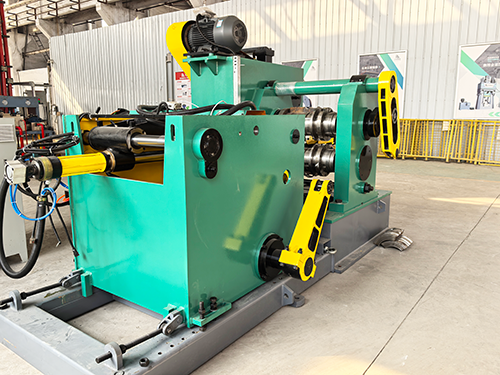

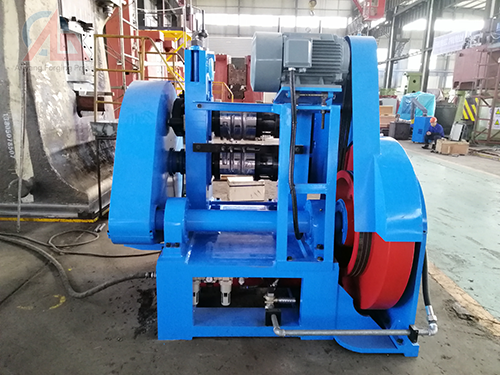

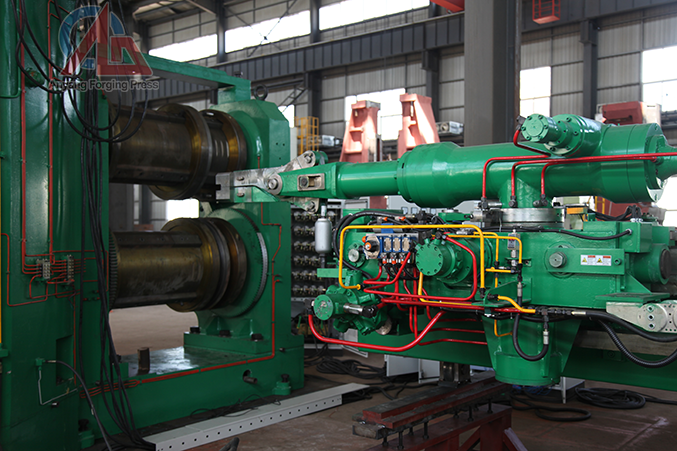

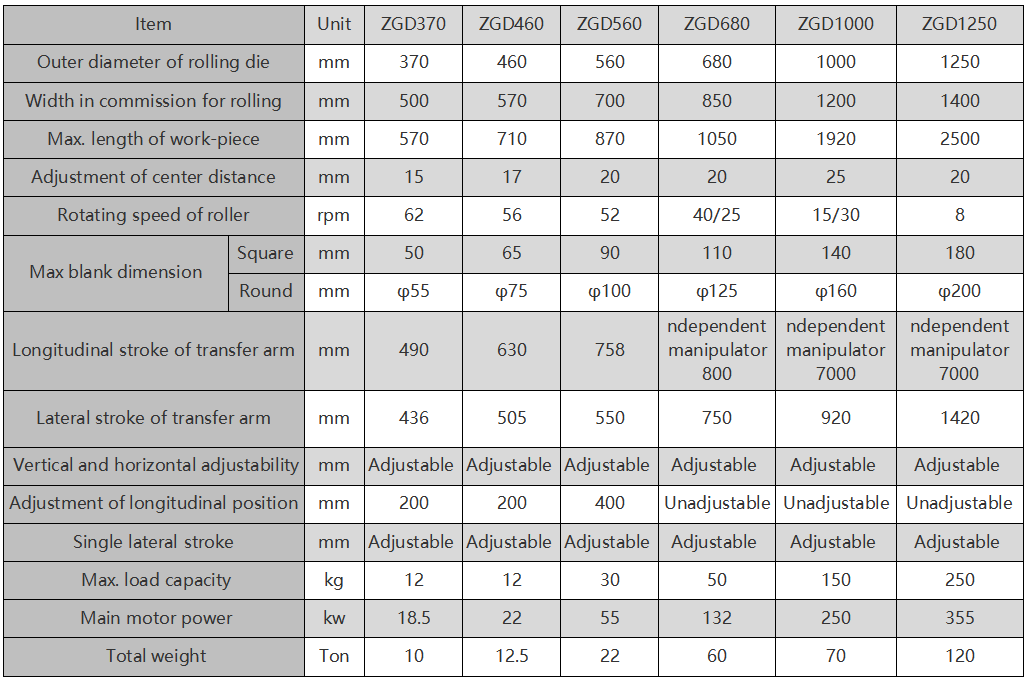

Roll forging machine is a metal forming equipment that uses two or more rotating rollers to compress and deform metal blanks to produce parts of various shapes. It is mainly used for continuous or batch production of medium-thick wall tubes, bars, plates, etc., and has the characteristics of high efficiency, energy saving and wide processing range.

The advantages of roll forging machines mainly include:

Continuous production: suitable for large-scale, continuous manufacturing, improving production efficiency.

Uniform forming: uniform metal deformation during rolling process to ensure product quality.

Energy saving and high efficiency: compared with other forging methods, it has lower energy consumption and saves costs.

Wide range of application: can process a variety of metal materials with flexible and changeable shapes.

High material utilization rate: reduce waste and improve raw material utilization rate.

High degree of automation: equipped with advanced control system, easy operation and strong stability.

The price of roll forging machines varies greatly depending on the configuration, brand, manufacturer, purchase volume and additional functions. It is recommended to contact the specific equipment manufacturer or supplier to obtain detailed quotation and technical support.

Felicia

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.