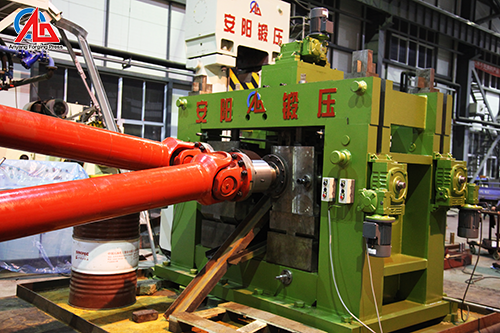

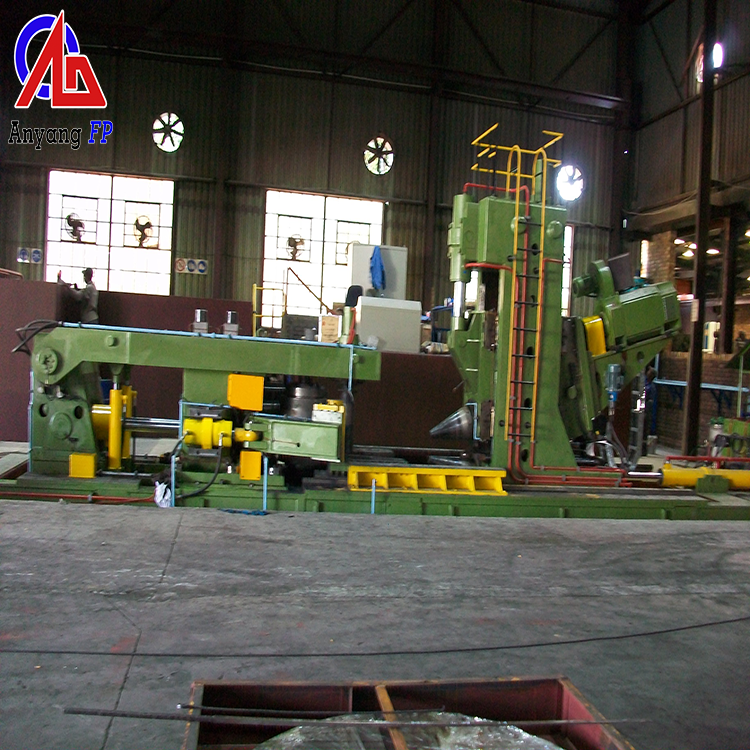

Skew rolling machine for grinding balls is a kind of equipment specially used for forging steel balls. It processes steel billets or blanks into spherical shapes through the skew rolling process. It has the characteristics of high efficiency and high precision. Its main features include high degree of automation, compact structure, fast production speed, uniform product size, and is suitable for mass production of high-quality steel balls.

Skew rolling machine for grinding balls features

Excellent surface quality: The surface of the steel balls produced is smooth and burr-free, reducing the subsequent processing costs.

High-efficiency production: high degree of automation, reduced manual intervention, large output, suitable for mass production.

Good mechanical properties: The forging process improves the internal structure of the steel balls, improves wear resistance, impact resistance and service life.

Energy saving and environmental protection: The use of efficient cross-section forming technology reduces energy consumption and waste, meeting the requirements of green production.

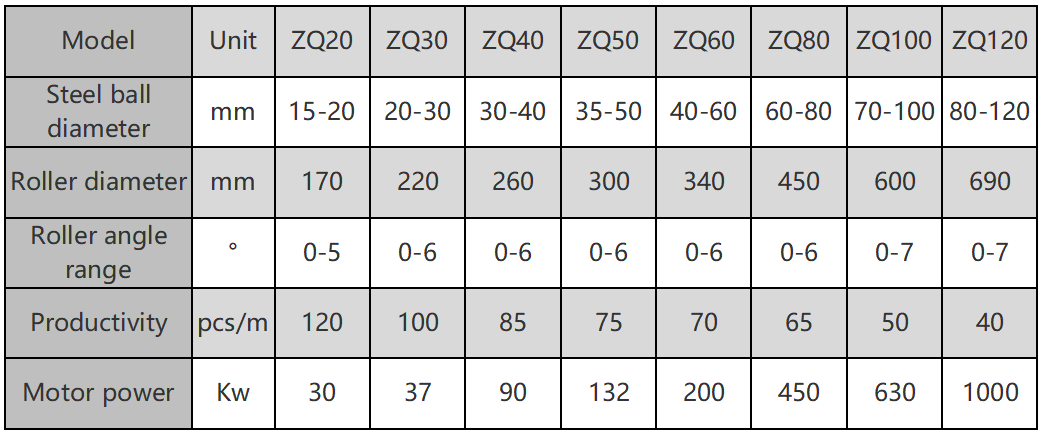

Diversified specifications: Steel balls of various sizes can be manufactured to meet different application requirements.

The price of skew rolling machine for grinding balls varies depending on the model, automation level, production capacity and configuration. The specific price also varies according to the specific configuration of the equipment, brand and the supplier’s quotation. It is recommended to contact the manufacturer or seller directly to obtain detailed quotation and technical solutions.

felicia@anyanghammer.com

WhatsApp: +86-13619834657

WeChat:+86 16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.