Forging manipulators are mainly used for billet clamping, handling, flipping and positioning, and can be used with open forging hammers and forging presses to achieve automated production. They are widely used in heavy machinery, aerospace, automobile manufacturing, energy equipment and other fields, greatly improving forging accuracy, production efficiency and operation safety.

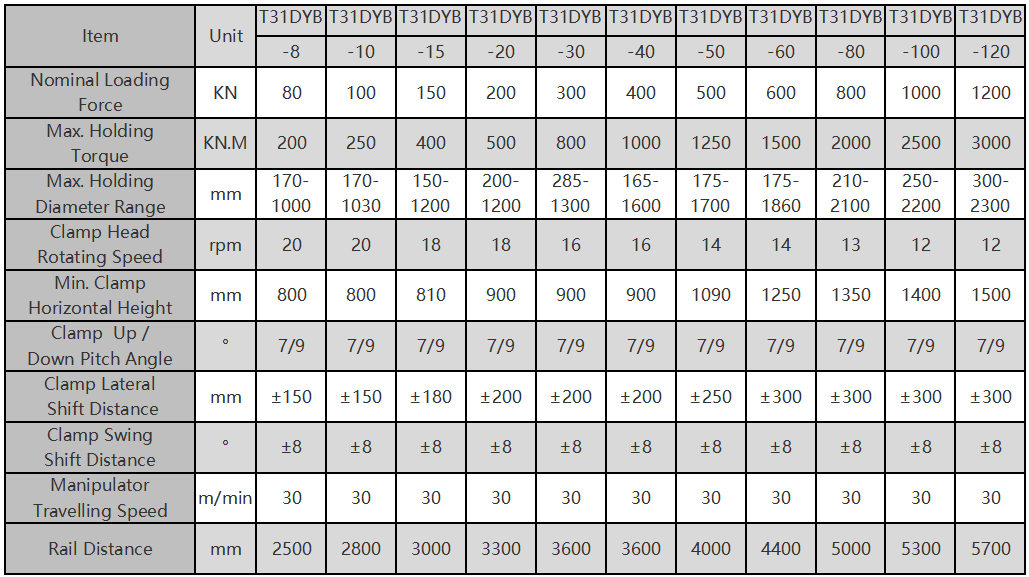

The performance parameters of the forging manipulator directly affect its application scenarios and quotations. The key parameters include:

Rated load: determines the maximum weight of the billet that can be handled. Heavy forging requires more than 20T.

Clamping diameter: Customize the clamp (mechanical clamp/hydraulic clamp) according to the billet size.

Repeat positioning accuracy: High-precision models are used for precision forging (such as aviation parts).

Drive mode: hydraulic/servo electric/pneumatic, hydraulic is suitable for heavy loads, servo electric has high precision, and pneumatic has low cost.

The quotation of forging manipulator needs to be evaluated based on technical parameters, customization and export costs. It is recommended to focus on load accuracy, high temperature resistance and localized service capabilities to ensure long-term stable operation of the equipment.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.