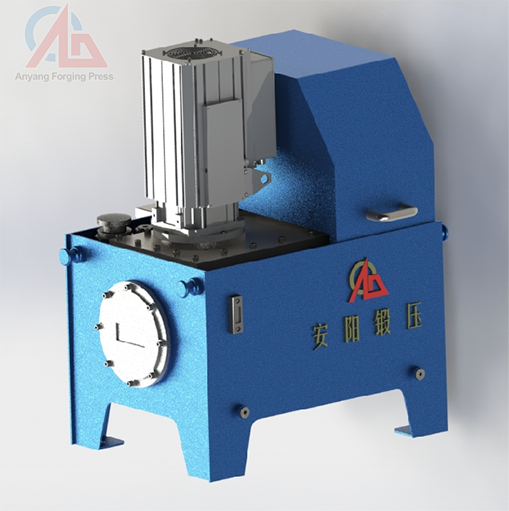

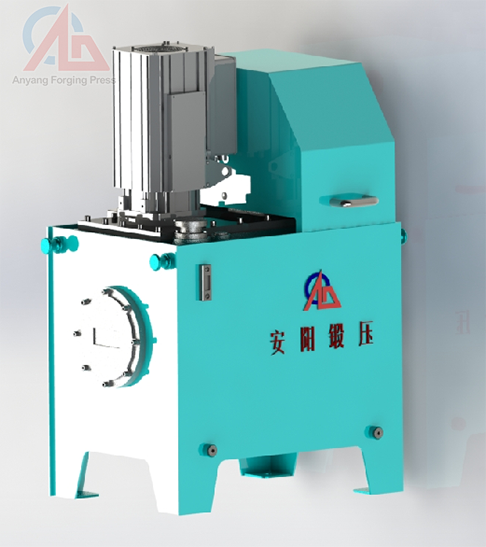

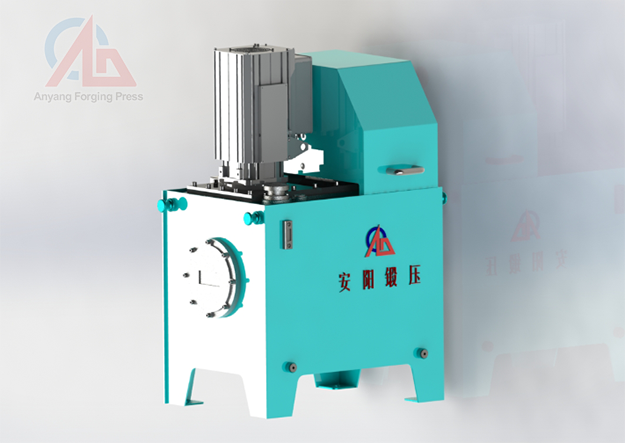

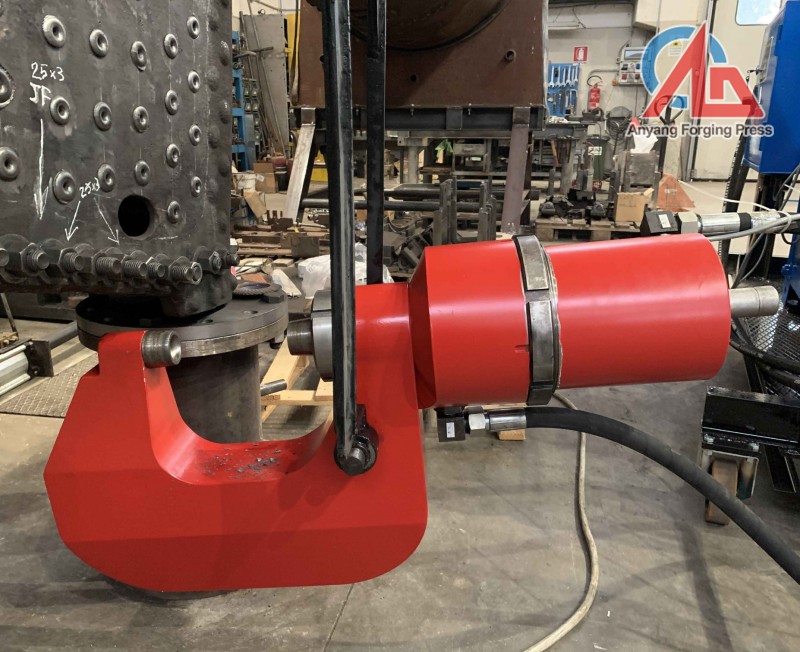

The suspended riveting machine utilizes the latest structure, offering powerful riveting capabilities, a stable and vibration-free process, and smooth, beautiful finished part surfaces. It features extensive adjustment features, including adjustable riveting pressure, feed speed, and riveting volume, as well as adjustable system pressure, ensuring optimal riveting results.

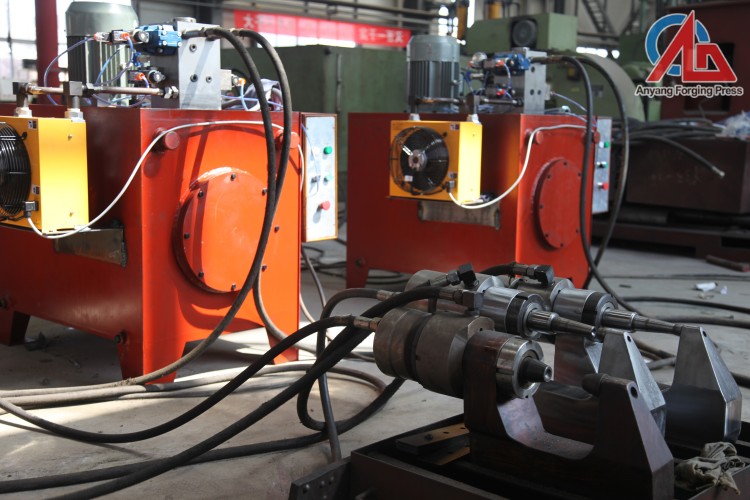

This riveting method, used in automotive frame riveting machines, frame riveting production lines, and frame riveting equipment, primarily utilizes the characteristics of the booster cylinder. When the piston rod moves forward unloaded, the oil pump delivers low-pressure oil at high flow rates. At this point, the system pressure is low. When the rivet head encounters the rivet, resistance increases, and the booster cylinder immediately activates to support the riveting. Once the riveting is in place, deformation resistance continues to increase. When the system resistance reaches the set value of the high-pressure system pressure sensor, the rivet head automatically retracts, completing the riveting process.

Frame riveting machine production line features

High Precision and Consistency

Through its high-precision mechanical structure and automated control, the position, force, and depth of each riveted point are guaranteed to meet standards, ensuring consistent and reliable assembly quality.

Flexible and Diverse Process Configuration

With multi-station, multi-task, and multi-program control capabilities, it can handle complex riveting processes for different vehicle frame models and structures, offering excellent process adaptability.

Compact Structure and Rational Design

The frame-type structure is compact and rational, facilitating overall line layout and space utilization, as well as ease of maintenance and operation.

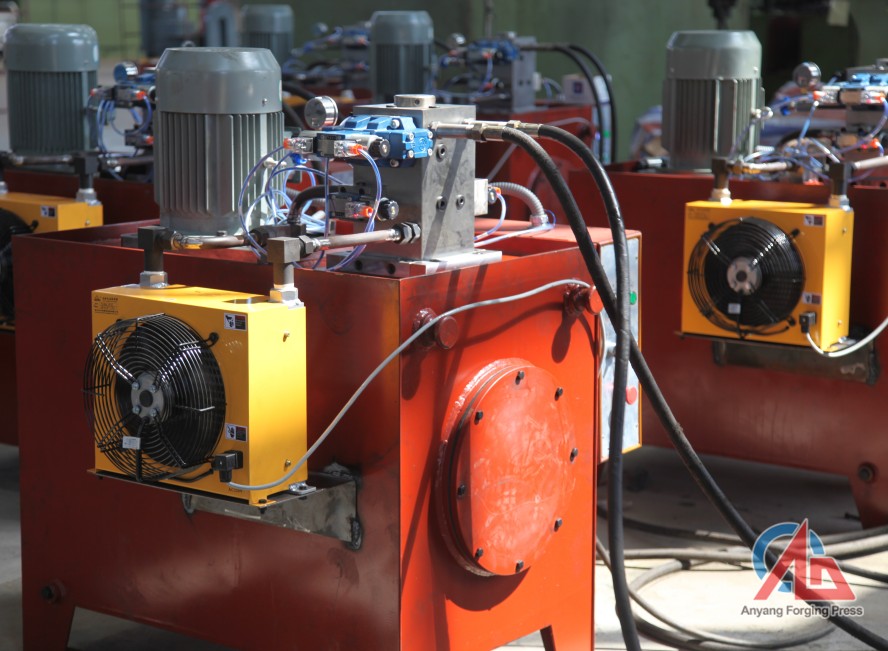

High Efficiency and Energy Saving

The highly efficient power system and optimized mechanical transmission mechanism improve production efficiency while reducing energy consumption, meeting energy conservation and environmental protection requirements.

Adaptable to Diverse Materials and Workpieces

It can process a variety of metal materials, meeting the riveting requirements of different vehicle frame types and improving material utilization.

The price of a carriage-type riveting machine production line is affected by many factors, including the degree of automation of the equipment, production capacity, equipment configuration, brand, manufacturer’s technical level, and customization requirements.

felicia@anyanghammer.com

WhatsApp:+86-13619834657

WeChat: +86-16692292870

This is my contact information. If you have any other questions or do not receive the quotation in time, you can contact me.